Environment

Society

Human capital

- Human Rights

- Development of Human Resource

- Development of Global Human Resource

- Diverse human resources and diverse working styles

- Health Management to Enhance Corporate Value

- Occupational Safety and Health

- Occupational Safety and Health

- business Continuity

- Business Continuity Plan/Management (BCP/BCM)

- communication

- Procurement Activities

- Stakeholder Engagement

- Social Contribution Activities

Governance

Technological Strengths

Basic Concept

Health and safety management is the basis of all our activities, an important part of our corporate foundation, and our corporate value.

Fujikura Group management and all employees will prioritize safety in conducting business activities, and will strive to create a safe and comfortable working environment and maintain and promote physical and mental health.

Fujikura Group Basic Principles for Safety and Health

1. We will comply with legal and other requirements regarding health and safety.

2. We will set specific goals related to safety and health, implement and evaluate them, and work toward continuous improvement.

3. We will conduct risk assessments in all unit and work to reduce risks.

4. We will promote the maintenance and improvement of physical and mental health, and will support the creation of a workplace environment in which Fujikura employee can work with enthusiasm and enthusiasm, as well as the health management of Fujikura employee.

5. We will allocate necessary resources and work to continually improve our occupational health and safety management system through employee consultation and participation.

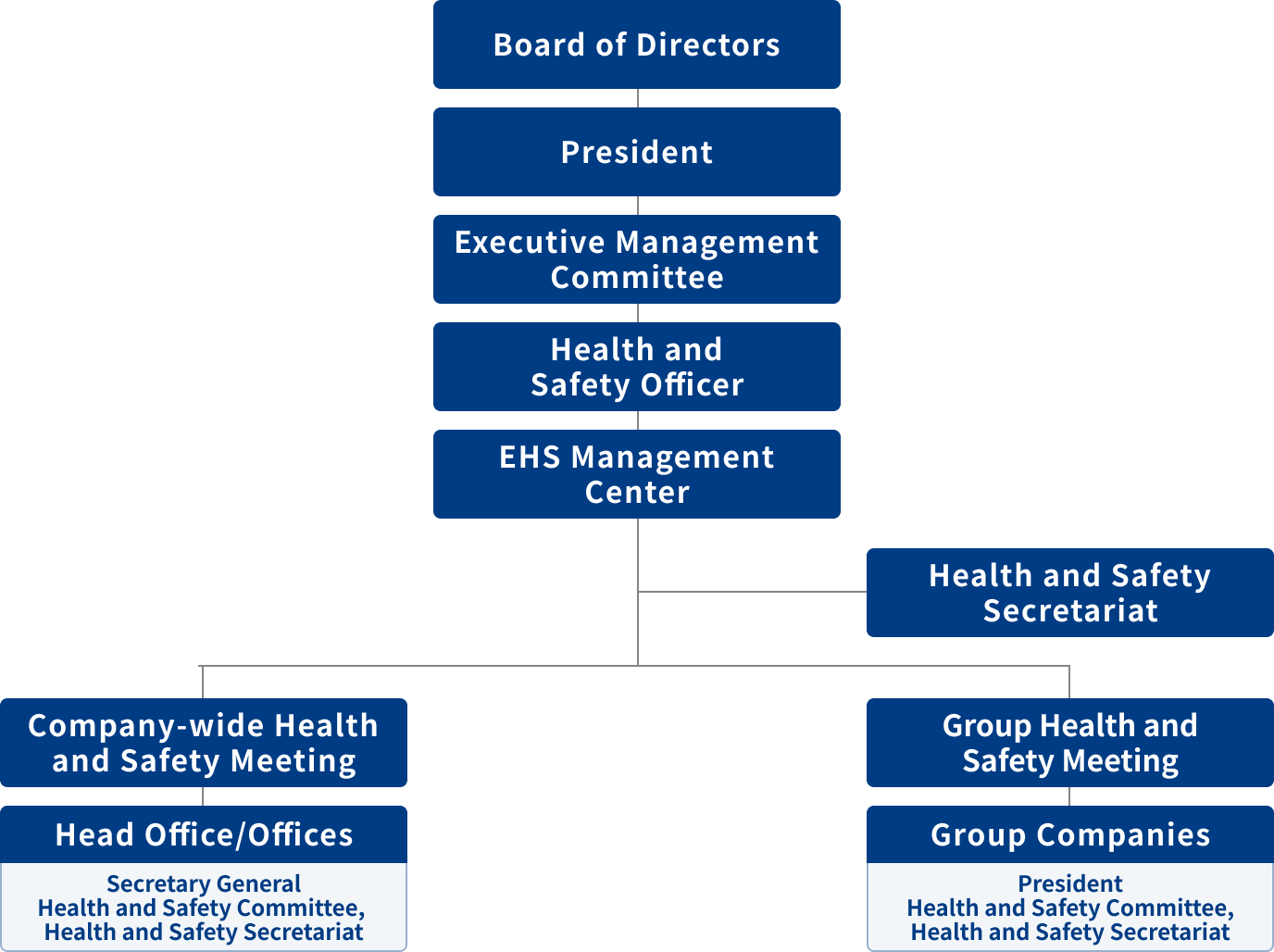

Safety and health activity promotion system

Fujikura Group safety and health activities are supervised by Board of Directors' Meeting, overseen by Director, President and CEO, and led by Environment, Health and Safety Management Center, which is strengthening group governance and improving the level of safety and health management.The Fujikura Group is working to improve safety and health management across the entire group, and to align the direction of these activities, messages from top management are conveyed, disaster information and other information is shared, and the Fujikura Group Safety and Health Conference is held twice a year as an opportunity for safety and health managers from each base to hold discussions.

establishment of "Safety Pledge Day"

In response to a serious accident that occurred at a domestic related company in April 2016, Fujikura Group Fujikura employee to pledge a strong commitment to safety and to "never let a serious accident happen again," and issued the "Safety Pledge" below. Every year on the same day, the Fujikura Group Fujikura Group establishment "Safety Pledge Day" (a message from the president) to all group companies both in Japan and overseas, and by reciting the "Safety Pledge," we hope to pass on the story of this incident and ensure it is not forgotten.

Safety Pledge

- We will never let the same disaster happen again!

- We prioritize safety in everything we do!

- We will create an accident-free workplace for our colleagues and their families!

Safety and Health Activity Slogan

Fujikura Group sets a new slogan for its safety and health activities every year and works to continuously improve the workplace environment and maintain and promote physical and mental health. For fiscal 2025, the slogan will be "Let's all share near misses and prevent dangers that did not lead to accidents," and top management has issued a message calling for the implementation of key safety and health measures at each base.

Health and Safety Initiatives

Inherent safety and risk assessment

In health and safety management, proactive activities such as risk assessment are positioned as important activities to reduce occupational accidents. Fujikura Group including overseas since 2016, we have continued risk assessment activities using a common method business and it has become an integral part of our activities regardless of the content and size of our sites. The risks identified have been assessed in a manner that is consistent with the company's essential safety standards. Risk reduction activities are conducted for identified risks based on the concept of intrinsic safety. All risks are managed and analyzed in a database system and utilized to promote risk reduction activities. The number of risks has increased from about 33,000 at the beginning of the data collection to just under 50,000 (including those that have become acceptable risks) as of the end of March 2025, an increase of about 51%. We will continue to work on potential improvement activities without slowing down.

We will continue to strengthen our activities to identify potential risks without slowing down, with the ultimate goal of "bringing all risks to an acceptable level.

Utilizing the Occupational Safety and Health Management System

We have been operating an OHSMS (Occupational Health and Safety Management System) since fiscal 2010, and in fiscal 2022 we obtained certification for the Occupational Health and Safety Management System standard (ISO45001-2018) within a framework that integrates our head office and each business site. The certification applies not only to Fujikura employee, but also to all parties who enter and leave each business site (non-regular employees, contractors, customers, service providers, etc.). We are effectively incorporating the requirements of the standard into operational improvements and efficiency in each business, and are utilizing the management system to ensure continuous improvement in order to build and foster a mutually enlightened safety culture in which all Fujikura employee can proactively point out each other's dangerous behavior.

*OHSMS: Occupational Health and Safety Management System

For more information, please click here.

Other major activities

group companies For the purpose of confirming the safety and health management activities of bases and the status of identified risks, as well as providing various types of guidance, the Environment, Health and Safety Control Center conducts regular safety and health inspections at all domestic and overseas bases. In relation to this, in order to grasp the activities at each site without omission, we have set up a system to collect necessary information at each site side by side by using the Environment, Health and Safety survey form. This Environment, Health and Safety survey form has been made more effective by updating the questions every year, and is also effectively used for health and safety patrols. We have been trying to prevent recurrence and similar accidents by sharing accident cases. In recent years, the number of accidents has been decreasing significantly due in part to the effects of the essential safety application, and we are also making efforts to share information on near-misses.

In addition, to foster a culture of safety, we are developing activities to raise the safety awareness of all employees at Fujikura and Group companies and to improve their competence. Hazard simulation training is said to be highly effective in improving sensitivity to danger, and by sending portable equipment to each Group site, a total of more than 8,000 employees will have taken the training by FY2024, making it an effective means of education.

Various initiatives to strengthen disaster prevention and countermeasures

Group Crisis Response/Disaster Prevention Review Meeting

The purpose of the meeting is to report, discuss and conduct training regarding Fujikura Group 's disaster countermeasures and crisis preparations.

Formulating Fujikura Group Disaster Prevention guideline

With the aim of strengthening countermeasures against natural disasters such as earthquakes and typhoons at each of Fujikura's business locations and group companies, we have formulated the Fujikura Group Disaster Prevention guideline, which stipulate rules and procedures for advance measures and for responding immediately after a disaster occurs (initial response).

Headquarters Disaster Prevention Headquarters Training

This training is being conducted with the aim of confirming and verifying whether the disaster system will function effectively by conducting an actual simulation of the action procedures of each team of the Headquarters Disaster Response Headquarters, which is responsible for activities such as ensuring the safety of human lives and preventing secondary disasters at the Headquarters in the event of an earthquake directly beneath the capital. The training begins with the assembly of each team member of the Headquarters after the earthquake occurs, and after each team member quickly assembles and quickly prepares the equipment necessary for the headquarters' functions, the headquarters is then established. By each team member actually carrying out the procedures expected in the event of a disaster, such as the individual procedures according to their role, the headquarters members confirm and learn their own roles and procedures.

At headquarters, information is collected on Fujikura employee safety, the status of buildings and infrastructure, surrounding traffic conditions, etc., and participants experience the difficulty and importance of organizing information through the consideration of countermeasures for various problems that arise, and issues for future improvement are identified. After the training is completed, the issues and points of reflection raised by each group, as well as areas for improvement for the next time, are shared and reflected in improvements to individual procedure manuals.

Disaster prevention training

As part of disaster prevention measures for the entire Fujikura Group, evacuation drills are conducted at the Head Office, Sakura business, Suzuka business and other locations, assuming major earthquakes such as a major Nankai Trough earthquake or an earthquake directly beneath the capital, in an effort to raise disaster prevention awareness.

Safety confirmation system and carrying a portable disaster prevention card

Fujikura believes that "each and every Fujikura employee is an important asset of Fujikura Group, irreplaceable by anything." Based on this belief, Fujikura is implementing various disaster prevention and mitigation measures in preparation for major natural disasters, such as the predicted imminent Nankai Trough megathrust earthquake and the Tokyo metropolitan area earthquake. Examples of these efforts include a safety confirmation system and portable disaster prevention cards.

Safety confirmation system

Fujikura has had a safety confirmation system in place to confirm the safety of Fujikura employee and their families in the event of a disaster since 2010. Information collected through this system is promptly reported to top management and used in BCP.

Portable disaster prevention card

Fujikura distributes disaster prevention cards to all Fujikura employee to protect themselves from major disasters such as earthquakes. The cards contain information such as actions to take in the event of a major earthquake (by affected area), a disaster prevention checklist, and how to respond to the safety confirmation system.