Environment

Society

Human capital

- Human Rights

- Development of Human Resource

- Development of Global Human Resource

- Diverse Human Resource and Diverse Working Styles

- Health Management to Enhance Corporate Value

- Occupational Safety and Health

- Occupational Safety and Health

- Business Continuity

- Business Continuity Plan/Management (BCP/BCM)

- Communication

- Procurement Activities

- Stakeholder Engagement

- Social Contribution Activities

Governance

Technological Strengths

Fujikura Group 's Clean Tech

Fujikura Group has responded to social issues such as the development of social infrastructure, and has contributed to the development of not only Japan, but also countries and regions around the world. In addition, we believe that solving global issues through the achievement of the SDGs is a great opportunity for Fujikura Group 's sustainable growth, and we are promoting CSV (Creating Shared Value) to improve social value and obtain economic value through our core business. In this article, we will introduce our Clean Tech initiatives, which have been attracting attention in recent years.

*Clean Tech refers to processes, products, or services that reduce negative environmental impacts through significant improvements in energy efficiency, sustainable use of resources, or environmental protection activities.

Fujikura Group 's Fiber Optic Cable support the 5G society

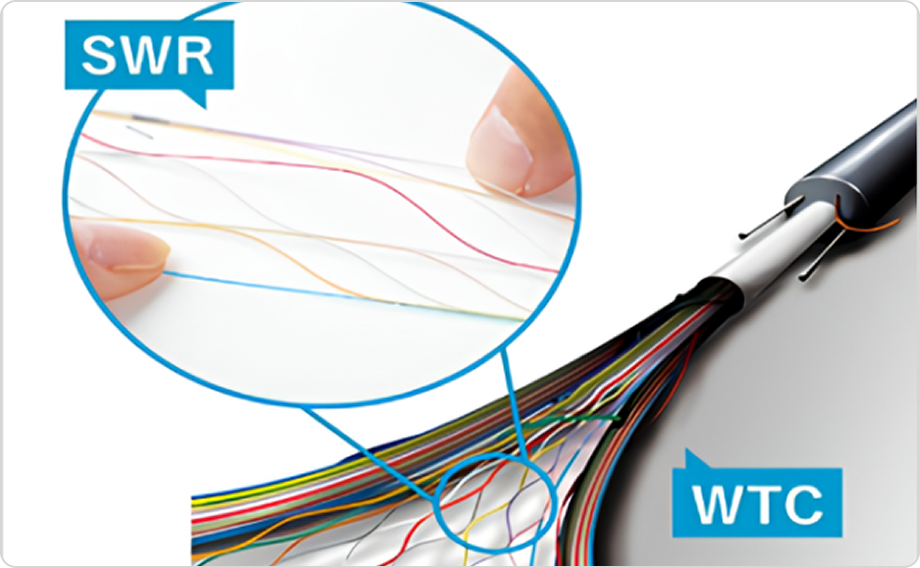

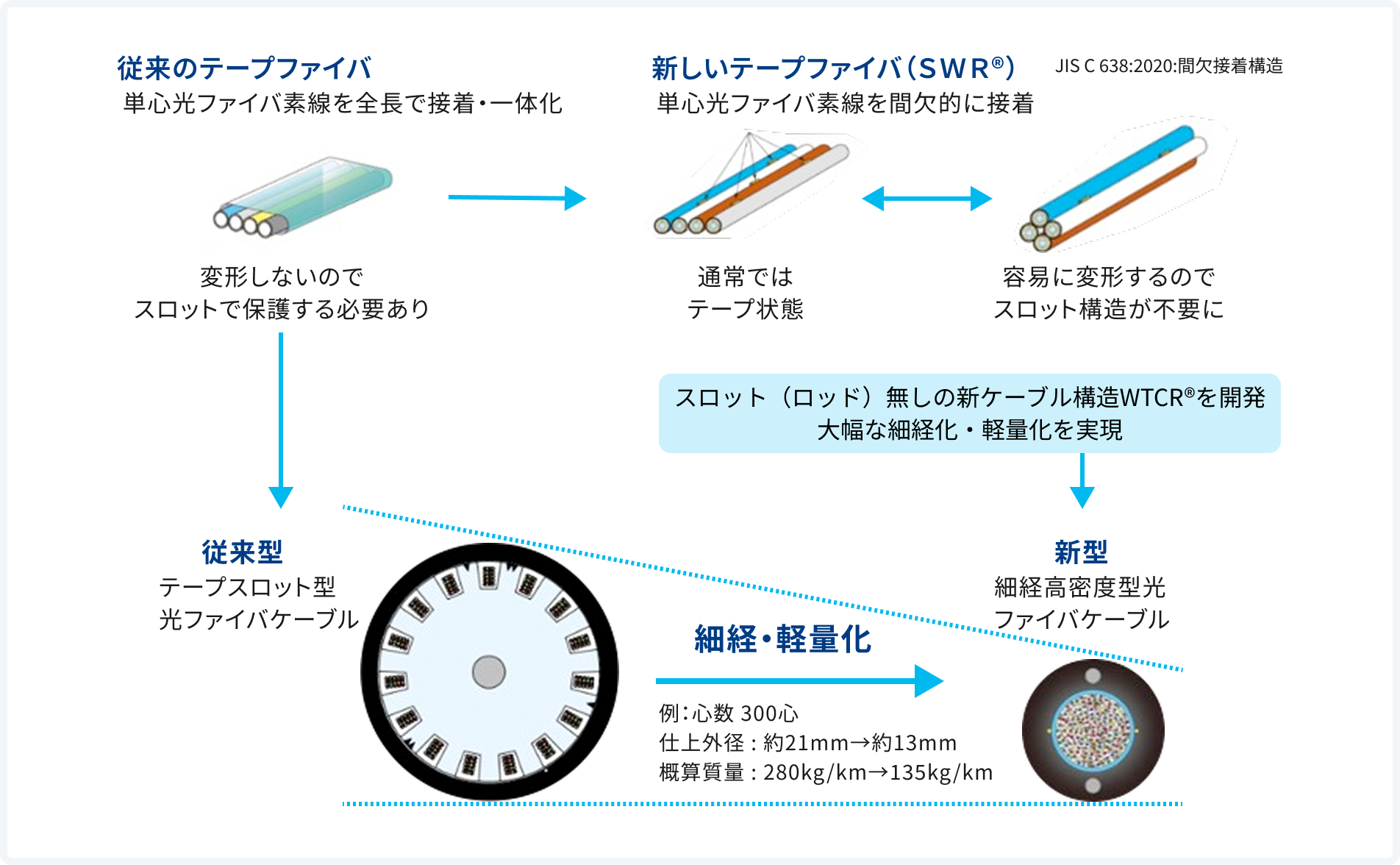

With the spread of various information and communication services such as 5G and IoT, demand for Fiber Optic Cable is expanding worldwide. Fujikura has commercialized Spider Web Ribbon™/ Wrapping Tube Cable™ (SWR™/ WTC™), the world's thinnest and highest density Fiber Optic Cable, as a technology for economically building optical Optical Fiber networks by making effective use of existing facilities.

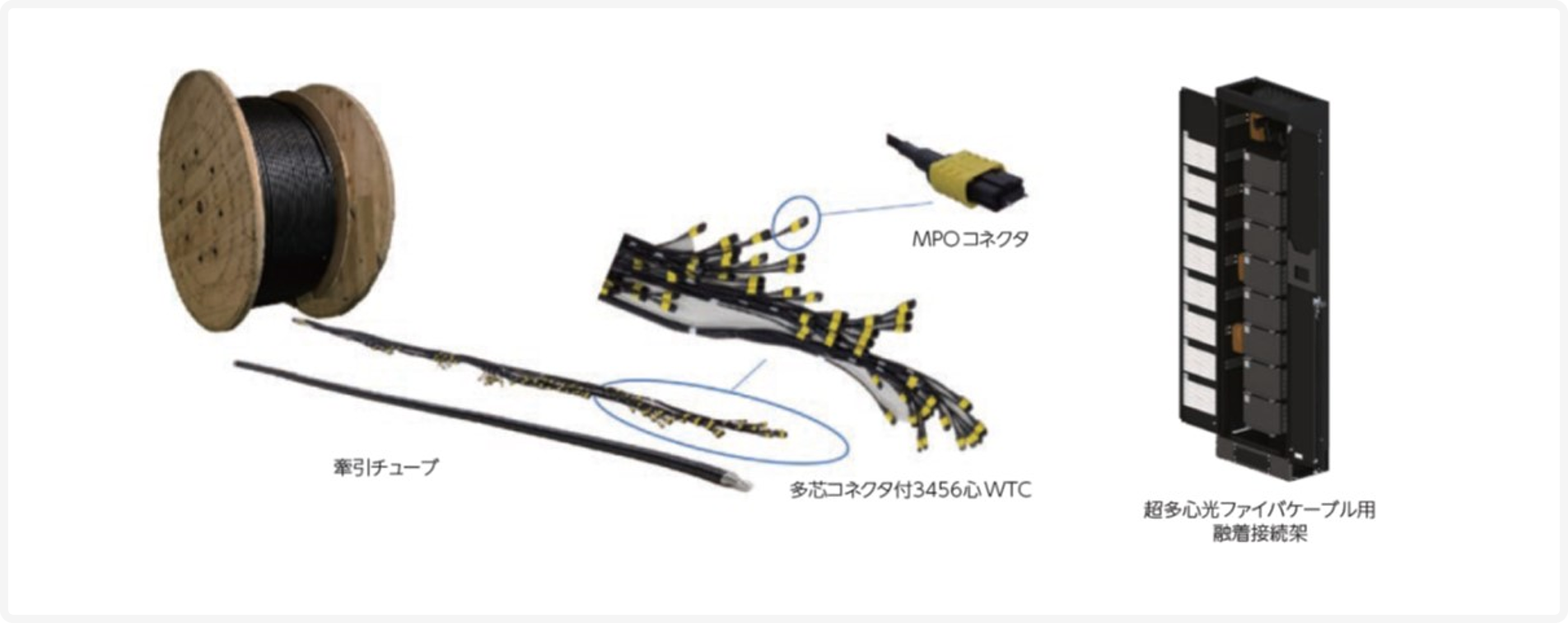

In fiscal 2020, we responded to the globally expanding demand data center by developing an ultra-high-core count optical cable using small-diameter optical Optical Fiber and an optical cable for indoor wiring with high flame retardancy that conformity with the European Construction Materials Regulation (CPR). Furthermore, we commercialized a 3,000-core Fiber Optic Cable, the largest in Japan, that is conformity with the domestic communications environment and achieves 1.5 times the density of conventional cables. We will continue to develop innovative Fiber Optic Cable based on SWR™/ WTC™ technology and contribute to the development of communications networks around the world.

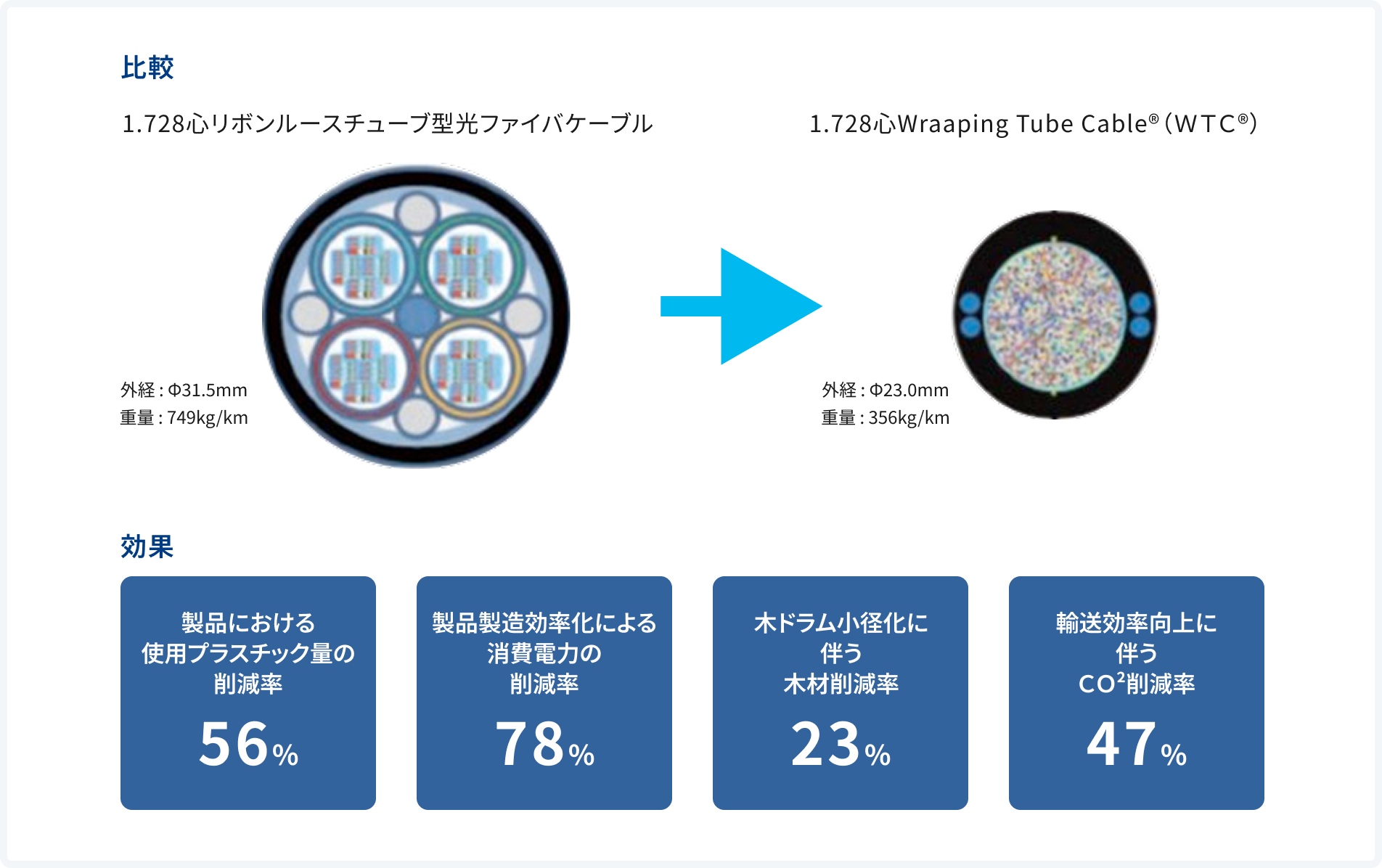

Reduces the environmental impact of manufacturing and transportation

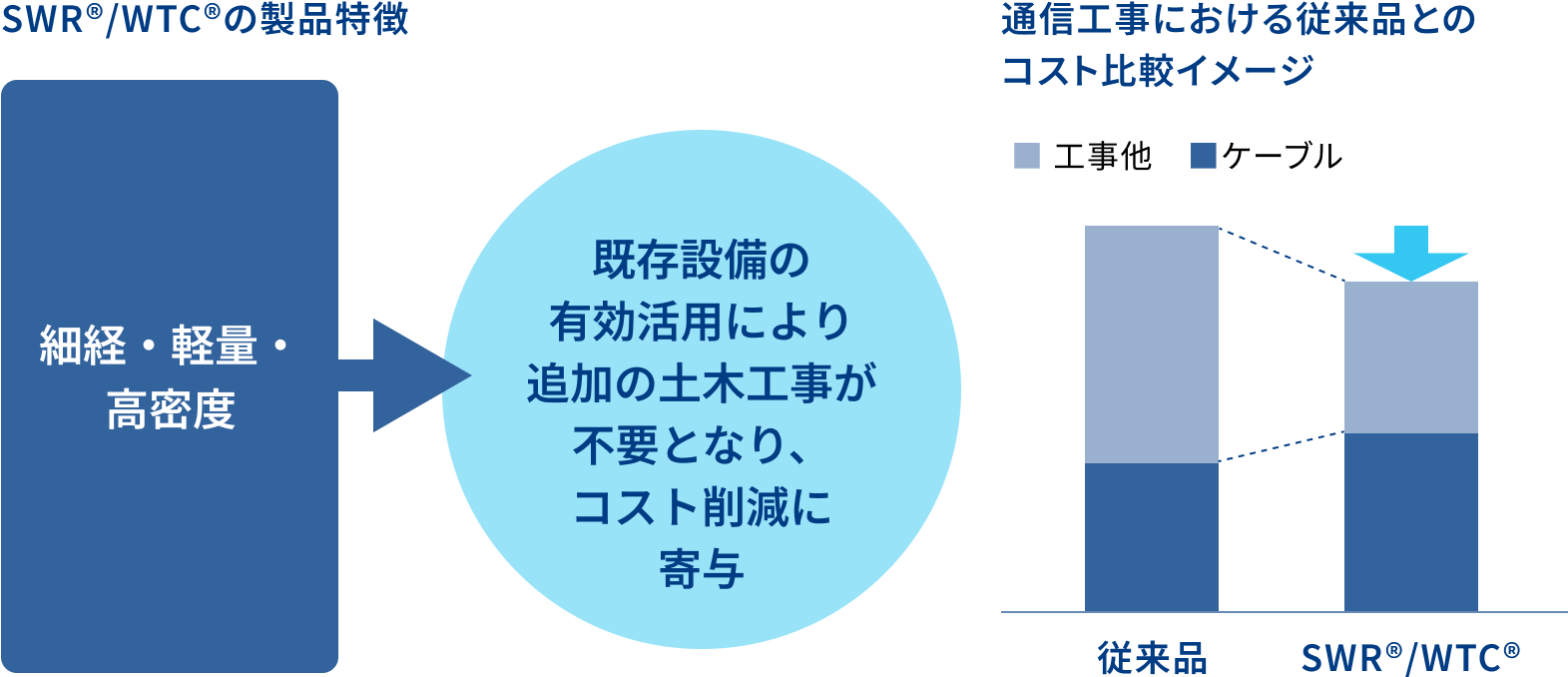

SWR™ / WTC™ also contributes to reducing the environmental impact through smaller cable outer diameters, lighter weight, fewer manufacturing processes, and application small-diameter drums.

Helps reduce your total cost of ownership (TCO*)

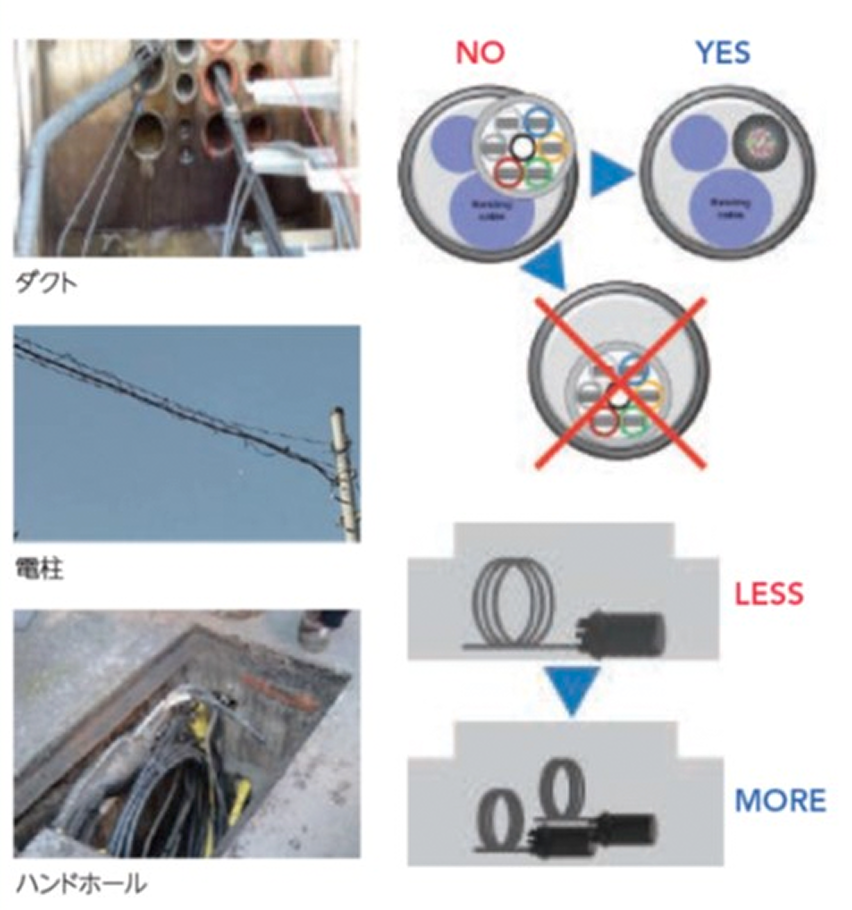

Our optical fiber cabling solutions business, centered on SWR™ /WTC™, also contributes to reducing customers' TCO*. Conventional telecommunications construction work required ducts and handholes to accommodate increased fiber capacity, which resulted in a high proportion of civil engineering costs. However, SWR™ / WTC™ is small and lightweight, so existing facilities can be utilized, eliminating the need for additional civil engineering work, thereby significantly reducing customers' construction costs.

*Total Cost of Ownership

Specific examples of TCO reduction

1 Duct Handhole

Increasing fiber capacity requires infrastructure to accommodate it, which incurs additional construction costs. However, SWR™/WTC™ allows existing ducts to be reused without the cost of installing additional ducts.

2 Handling advantages

SWR™/ WTC™ is a small and light cable, so laying work can be done with fewer workers than before.

3. Transportation Advantages

SWR™/ WTC™ is a small and light cable, which also contributes to reducing Butsuryu costs.

4.Reduction of work load during laying

SWR™ /WTC™ can be made long, which reduces the number of times cables need to be spliced together during cable laying, helping to reduce the workload.

Synergistic effects with peripheral devices

Our optical wiring solutions, centered on SWR™ /WTC™, meet customer needs and reduce environmental impact through synergistic effects not only with cables but also with peripheral products.

Concentrating management resources on optical wiring solutions business

We have determined that the business of optical wiring solutions, mainly SWR™ /WTC™, mainly in Europe and the United States, is an area where management resources should be concentrated, and this business is Fujikura's core area. As many customer continue to feel better, we will continue to expand our business by creating more differentiated products.

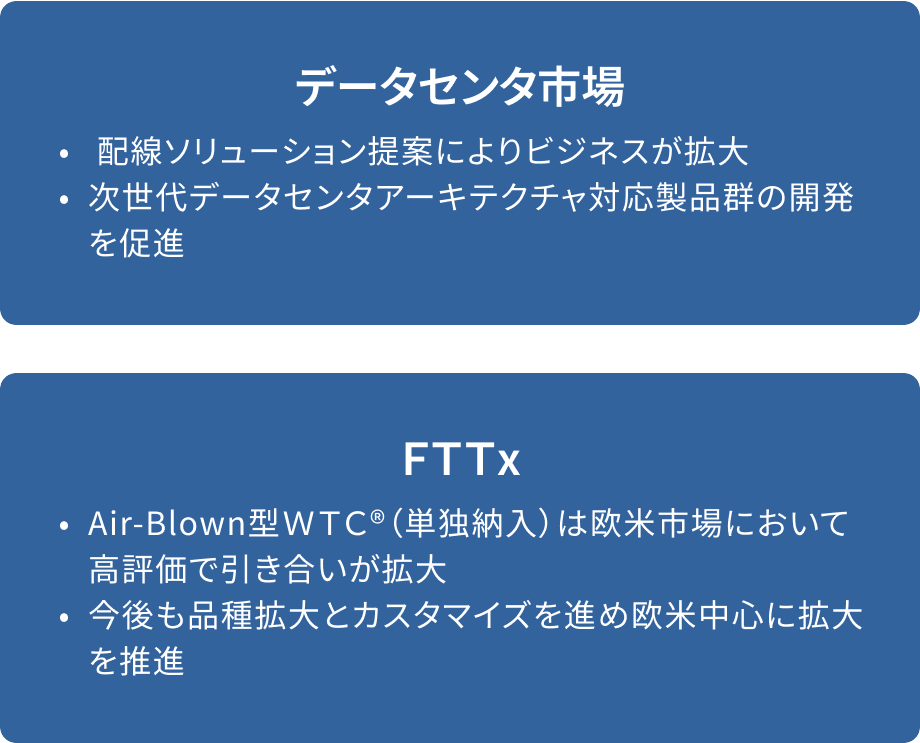

Focus Markets

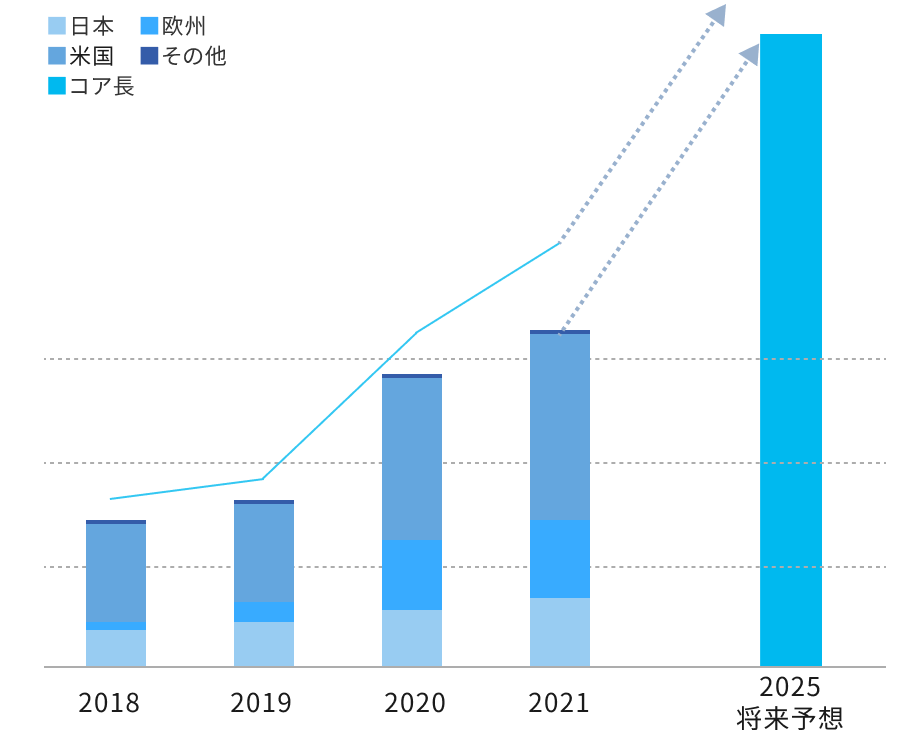

SWR™/ WTC™ sales trends by region

Relocation and expansion of overseas manufacturing bases and establishment of new production lines

AFL Telecommunications Europe Ltd., a UK group companies, has relocated and expanded its optical cable factory and installed a new production line, which has now begun operation. The new line produces Air Blown Wrapping Tube Cable™ (AB-WTC™), a small-diameter, high-density Optical Fiber ribbon cable that is air-blown*, and will contribute to the construction and development of FTTx and 5G networks in the UK and Europe. The start of local production will enable Fujikura Group to provide more comprehensive customer service to its European customers, and further improve its ability to provide a stable supply to customers by strengthening its supply chain. The start of local production will also contribute to revitalizing the local economy and creating new jobs.

*Air-blown type is a method of laying optical fiber cables in which compressed air is blown into the conduit to pressurize the optical fiber cable. This method is widely used mainly in Europe and the United States.

Promoting CSV

Fujikura Group is promoting CSV (Creating Shared Value) as a strategy to solve social issues and contribute to the achievement of the SDGs along with Fujikura 's profit growth. CSV is defined as an activity in which a company improves social value (solving social issues) and gains economic value (profit) through its main business. Fujikura Group has continued to engage in business activities to solve social issues, and 2017 has been designated as the "first year of Fujikura Group CSV" and is the year to start thinking about CSV in earnest. and Corporate Officer.

Local government initiatives to solve social issues

Partnership agreement concluded with Omachi City, Nagano Prefecture

Fujikura signed a collaboration agreement with Omachi City, Nagano Prefecture, in October 2018, aiming to launch new services that will contribute to improving public services using ICT and IoT. The company has begun efforts to realize social implementation while confirming technological and administrative challenges through demonstration experiments. Through open innovation, the company is working to create new business by selling services.

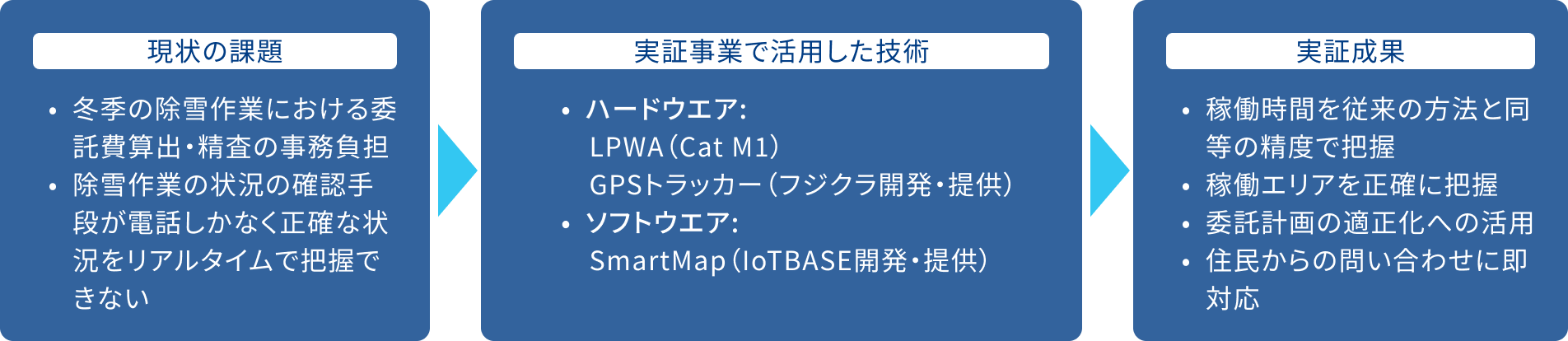

IoT demonstration experiment conducted to improve snowplow management operations

As one of the demonstration experiments, we have been working with IoTBASE Inc. since January 2019 to solve the issue of "appropriate evaluation of snow removal costs" using GPS*1 devices.

Omachi City is located in a snowy area where the average snow depth in February exceeds 50cm, placing a heavy burden on snow removal work in winter. In this project, we worked on automatically calculating operating hours by grasping the location information of snow removal vehicles in real time, and conducted a demonstration experiment with the aim of utilizing the system for purposes such as optimizing operation routes by grasping work areas and responding quickly to inquiries from residents.

The results of the demonstration experiment confirmed that it is possible to systematize snow removal operations in an inexpensive manner, improve the cost estimation work of local government offices and contractors, and potentially improve services for residents.

Based on the results of this demonstration experiment, Fujikura and IoTBASE aim to commercialize a location information solution for local governments that can be used for snow removal business and other purposes.

The flow of business creation in Ono City, Nagano Prefecture

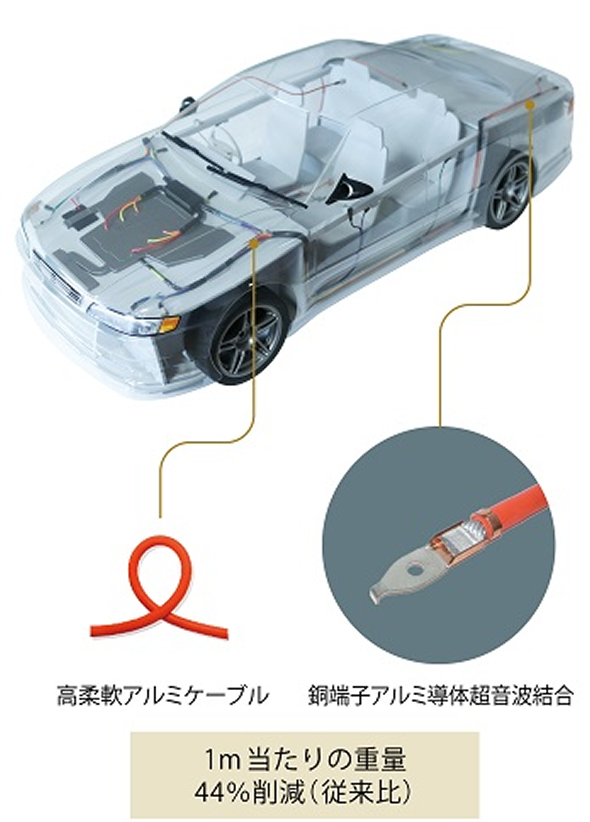

Contributing to a low-carbon society through lightweight aluminum harnesses for electric vehicles

Fujikura has begun mass production of aluminum harnesses for electric vehicles in order to contribute to a low-carbon society through the development and manufacturing of products related to electric vehicles.

Just as with gasoline-powered vehicles, there is strong market demand for lighter harnesses and lower circuit resistance in electric vehicles in order to improve fuel efficiency (electricity cost). Furthermore, as the number of devices increases with electrification, the space available for wiring harnesses inside the vehicle is continuing to decrease, so there are growing expectations for harnesses that are easier to bend.

This harness meets these needs, and while it has made the cable conductor lighter by changing it from conventional copper to aluminum, it also solves two problems that arise when using aluminum - "reduced flexibility due to an increase in the cable outer diameter" and "increased connection resistance due to the oxide film on the aluminum surface" - by using a newly developed highly flexible thermoplastic elastomer insulator and ultrasonic bonding technology between the copper terminals and aluminum conductors. Compared to conventional soft copper wire, this harness is easier to bend and has reduced connection resistance.

Contributing to the spread of compact, next-generation MRI devices that do not use natural resources (liquid helium) in the medical field

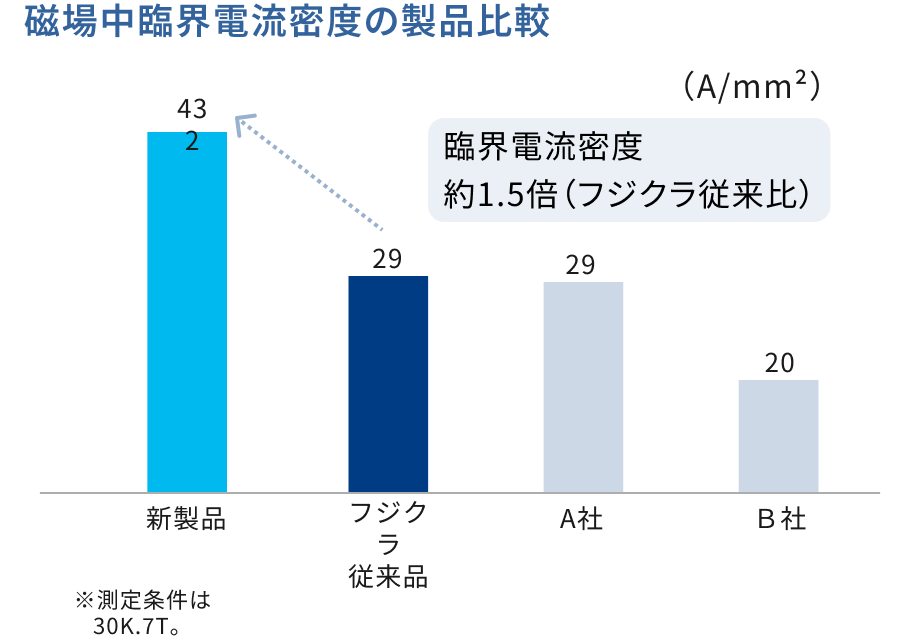

Fujikura has successfully developed the world's highest performance rare earth high-temperature superconducting wire technology of over 400 A/mm2, which has a critical current density of about 1.5 times that of the conventional sales in a low-temperature magnetic field, exceeding 400 A/mm2. Superconducting technology is used in MRI (Magnetic Resonance Imaging) equipment in the medical field and silicon crystal furnace lifting equipment in the semiconductor field.

In FY2016~18, Fujikura received a development business from the New Energy and Industrial Technology Development Organization, and has been developing rare earth high-temperature superconducting wires aimed at application for MRI equipment.

High-temperature superconducting MRI equipment has already been successful in acquiring images with small devices, and this time, by reaching a critical current density of 400 A/mm2 in a magnetic field, it has reached a level where compact next-generation MRI equipment that does not use natural resources (liquid helium) can be realized.

Fujikura will continue to expand its high-temperature superconducting business by providing rare earth-based high-temperature superconducting wires and coil products to meet further demand growth.