Technology Areas/Product Groups

Manufacturing Design

In new product development, the key to differentiation is to promote product development and production technology development at the same time. Fujikura has high technical capabilities related to equipment development, such as mechanical design and electrical and control design, and is working on the development of unique equipment that is not available in the world. We are continuously working to deepen the Fujikura's unique equipment technology and acquire advanced external equipment technology, and take on the challenge of developing advanced equipment by incorporating these technologies into Fujikura 's own production facilities tailored to our products. Through the provision of production equipment and production technology, we will focus on strengthening the profitability of each business units and R&D unit and developing competitive new products.

Furthermore, in response to the recent decline in the working population, there is a demand for further automation of manufacturing processes.By replacing tasks that have previously been performed by humans with specialized machines, robots, automatic transporters, etc., we will provide production technologies that simultaneously achieve improved productivity, stable quality, and labor savings.

Precision Machining Technology

In the field of manufacturing increasingly high-precision products, precision-machined parts, jigs, and molds are used to minimize process variability and achieve high productivity and yield.

We make full use of high-precision cutting, grinding, electrical discharge machining, and measurement technologies to differentiate our products by in-house production of high-precision fixtures that are essential for Fujikura's Optical Fiber manufacturing and turning them into black boxes. In addition, various molds such as molding, punching, and progressive delivery are produced within the Fujikura Group, which makes it possible to improve product accuracy.

This precision machining technique is also utilized in the manufacturing of electronic components. Fujikura manufactures cutting tools designed in-house, and manufacturing tens of millions of electronic components annually with high process capabilities.

In the field of R&D, we are working on the development of precision machining methods for difficult-to-cut materials such as heat-resistant alloys and rare metals, as well as new materials, using a variety of high-precision machining machines, including high-speed machining machines capable of machining with a high precision of 1/1000 mm or less.

Through the development of precision machining technology, we provide high-precision fixtures, parts, and machining methods, aiming to achieve differentiated products and manufacturing processes.

Control Technology

At Fujikura, we utilize advanced control technologies to develop in-house manufacturing equipment. manufacturing equipment requires more sophisticated and precise products, consistent quality, labor savings, and, most importantly, operational safety. Therefore, we proactively incorporate advanced control technologies such as high-speed, high-precision speed control and positioning control, and are working to reduce the number of workers and automate factories by building control systems for robots and automated guided vehicles. Furthermore, to acquire digital data from manufacturing equipment (FA layer), we work closely with Monodukuri sites and obtain useful data through optimal sensing. Furthermore, by adding value to the acquired data, we are promoting "Monodukuri DX" and working to make manufacturing equipment more intelligent.

Inspection Technology

Products in the information and communications and energy sectors require a consistent high level of quality to support a stable social infrastructure. Similarly, in the electronics and automotive sectors, as products become more sophisticated and denser, it is necessary to accurately detect even minute defect and quality changes to prevent the outflow of defect. Both types of products require rigorous and strict quality control (QC) and continuous quality improvement, making it important to develop optimal inspection methods tailored to aspect of each product.

At Fujikura, the Production Technology unit plays a central role, working in cooperation with all relevant unit, including product development, manufacturing sites, quality assurance (QA), and inspection technology, to develop unique inspection methods tailored to aspect, manufacturing processes, and inspection standards of each product. We have also introduced highly sensitive and highly accurate inspection equipment for a wide range of in-house manufacturing processes. Furthermore, we are developing and introducing a production system that visualizes quality trends from inspection results and utilizes them to improve quality.

Material Analysis Technology

By utilizing MI (materials informatics) in materials technology, Fujikura is strengthening its Monodukuri and contributing to society. MI is an approach that actively utilizes computational science and data science. Materials technology involves elements such as material design, process design, measurement, and analysis, and therefore requires the use of appropriate data analysis methods for these. Therefore, Fujikura has positioned MI as one of its fundamental materials technologies and is promoting its application to a wide variety of products. For example, by utilizing Bayesian optimization in the development of cable sheaths, we have succeeded in shortening development time to approximately one-quarter of the previous time.

Analysis Technology

Computer simulation* analysis, increasingly used in product development, manufacturing and processing technology development, and defect cause investigation, enables invisible phenomena and changes that can only be imagined to be visualized and then understood and examined. This method is extremely useful for obtaining optimal product design solutions and shortening product development times. Computer simulations used in the design and improvement of manufacturing processes combine multiple physical phenomena, such as understanding changes in shape and stress distribution due to vibration, and simultaneous coupled analysis of fluid behavior and chemical reactions in raw materials. Ensuring analytical accuracy for these complex phenomena presents a technical challenge. By feeding actual manufacturing data back into computer simulations, we are accumulating unique analytical techniques and know-how to improve analytical accuracy. We utilize a variety of analytical techniques, including those for stress, displacement, strength, vibration, current, heat transfer, and fluid dynamics, to develop differentiated products and production technologies.

Computer simulation: The use of computers to simulate phenomena and events that are difficult to calculate manually.

AI technology

In recent years, due to the rapid spread of AI technology, more and more companies in the manufacturing industry have introduced AI into their production processes. Therefore, Fujikura is implementing AI technology developed by Fujikura into the company's manufacturing processes to dramatically improve quality and productivity.

One of Fujikura's competencies in AI technology is its ability to acquire the latest AI and application it as a solution to solve real business problems. Specifically, in 2018, we introduced a visual inspection application into our manufacturing process, and since then, we have developed and implemented multiple AI-based visual inspection systems for a wide range of internal products[1]. In addition, Fujikura has developed its own "AI Platform" to monitor whether the developed AI solutions are operating normally and to stably operate and maintain AI inspections.

Discrimination AI is one of Fujikura's key technologies, and its concept is shown in Figure 1. During learning, a large number of pairs of images and their corresponding accurate information are input into the network. As learning progresses, it becomes able to output results for input images with high accuracy. This technology is used for visual inspection in Fujikura's manufacturing processes.

Figure 1: Image recognition using deep neural networks

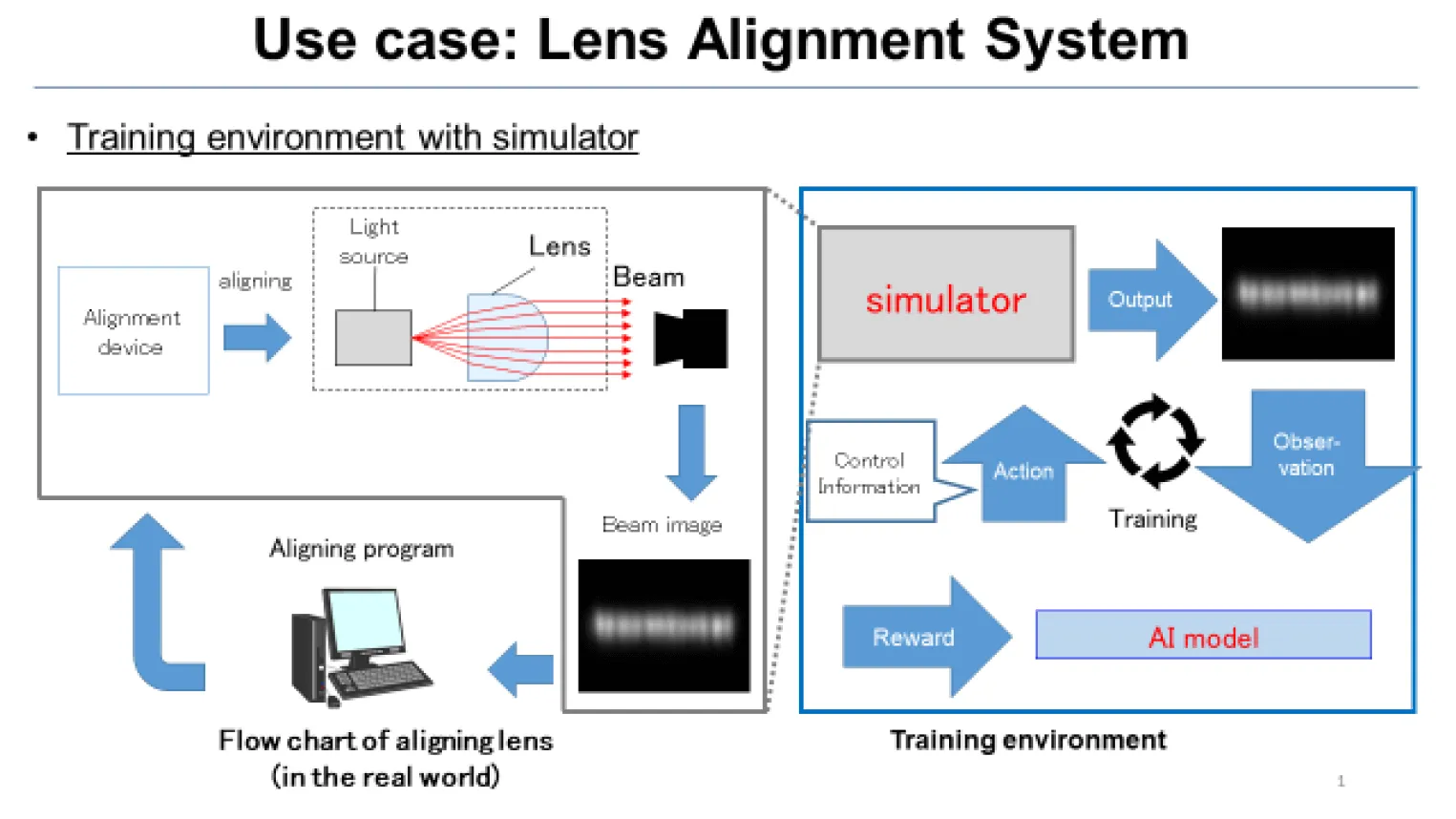

We are also working on developing applications using reinforcement learning and Sim2Real technology (Figure 2). These technologies have the potential to broaden the scope of AI application, as they can use aspect determined by AI to control manufacturing equipment. Fujikura has conducted proof-of-concept testing to introduce this technology into a lens alignment system [2][3].

Going forward, we will continue to keep up with the ever-advancing AI technology and utilize AI to address issues that arise in our Monodukuri and business processes, thereby improving operational efficiency and productivity.

References

- Kurosawa et al.: "Methods for promoting AI and technological development for its realization," Fujikura Technical Report, 2021

- T. Akiyama, "Practical Use Case of Reinforcement Learning and Sim-to-Real Transfer for Manufacturing," NVIDIA GTC, 2023

- Nitawaki et al., "application of AI control technology using reinforcement learning and Sim2Real to manufacturing equipment," Fujikura Technical Report, 2024