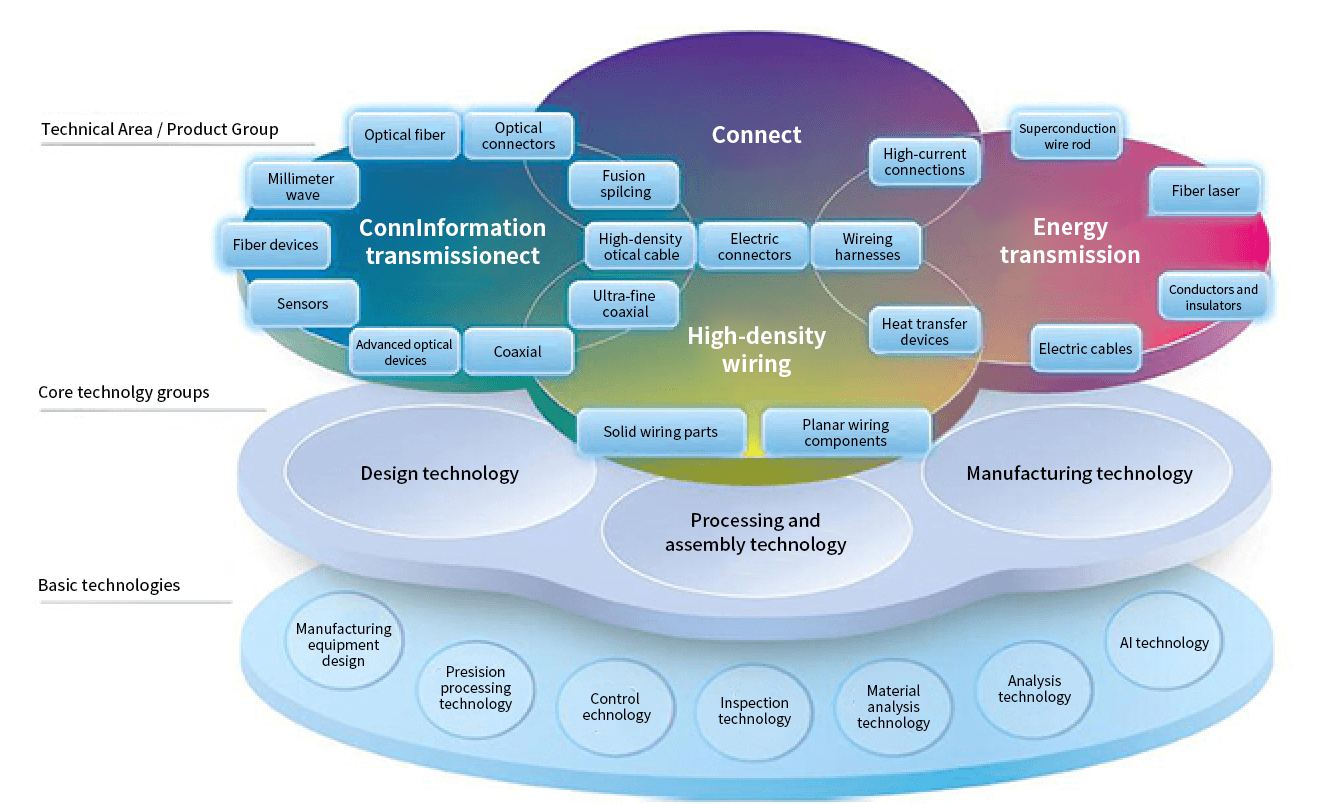

Technology Areas/Product Groups

Developing Core and Fundamental Technologies Based on Our Technology Platform

Since assuming the position of CTO in 2022, Fujikura's R&D has been working on four key issues: "group-wide technology management," "strengthening product development capabilities in cooperation with business units and production technology unit," "building a framework for creating new technologies and new business," and "reforming R&D governance and organization culture," to advance R&D activities. I have been promoting the advancement of R&D activities under the following four themes. Here, I would like to explain these efforts, which I feel have been successful.

Fujikura Group began with electric wires and has expanded into a wide range of fields, including information and business, primarily optical fibers, energy, electronics, and automobiles. Each product offered in these business is based on core technologies that support business. Fujikura's technology originates in electric wire technology. Specifically, it includes electric wire design technology, electric wire processing technology such as extrusion and twisting, and electric wire manufacturing technology. Fujikura has independently created and evolved these technologies. Subsequently, as the company expanded business into fields other than electric wires, it has developed core technologies for each business, such as glass synthesis technology and spinning technology for optical fibers. Furthermore, it has applied the material technology and manufacturing equipment development technology cultivated in electric wires to new business outside of electric wires. These technologies are organized into the "Technology Platform," Fujikura's research and development blueprint, created in 2023.

Fujikura's "Technology Platform" consists of three layers. The first layer is the technology domain and product group. It defines four areas of focus: Fujikura's traditional technology domains of "information transmission" and "energy transmission," as well as Fujikura's recent strengths in "connection" and "high-density wiring." The second layer is the core technology group. It defines "design technology," "processing/assembly technology," and "manufacturing technology" as technologies that Fujikura should leverage in each business field and new field. These technologies are used to create new technologies in R&D and business division development, and to refine existing technologies. The third layer is the foundational technology group. These technologies, such as manufacturing equipment design technology and precision processing technology, have been accumulated by Fujikura over the years and can be shared across business and new developments. The purpose of R&D is to create new business and products unique to Fujikura in the areas defined in the first layer. To achieve this, we aim to enhance customer value by refining the core technologies in the second layer and to revitalize R&D activities by improving R&D efficiency through the foundational technologies in the third layer.

Utilizing the technology and knowledge cultivated in each business in other business and products is extremely important for improving the efficiency and effectiveness of research and development. To do this, it is, of course, necessary to know about other business units and their products and technologies. Looking back at the core technologies that Fujikura possesses, I realized that there are far more than I had imagined. Moreover, the development of each core technology and each of the products that have been created from it all have their own unique stories, such as their history and background, or the difficulties they faced in creating them. R&D staff tackle various problems and challenges every day, and knowing these stories is extremely stimulating and will surely be useful in overcoming them.

In 2023, we launched the "Technology Group Meeting" as a forum for engineers from the R&D unit, each business units, and production technology division to discuss and mutually understand the technologies they each possess. Thirty to forty core engineers from each unit participate in this meeting to hold discussions. The R&D unit and each business units share similar core technologies; for example, adhesive technology is widely used in each business units as a technology for constructing products. By having engineers from different unit discuss the use, aspect, and challenges of adhesives, they are able to gain a deeper understanding, leading to new discoveries.

As the CTO in charge of technology management, I would like to organize the content of the discussions and ultimately create a technology database that can be shared by anyone in the company. I believe that this initiative for "group-wide technology management" will also lead to "strengthening product development capabilities in collaboration with business units and production technology unit."

Technology Platform

Important R&D themes with an eye to the future

We are working on multiple development themes that support the current situation and address future developments, but we have set three key R&D themes: next-generation optical communications, next-generation energy, and millimeter-wave applications.

Regarding next-generation optical communications, we are developing multicore fibers, which have multiple cores arranged in a single optical fiber, to cope with the rapid increase in data volume circulating around the world. Fujikura is already able to manufacture multicore fibers themselves, but because optical fibers alone do not constitute a system, we are also focusing on developing peripheral technologies, such as multicore fiber connection technology, with the goal of completing the technology as a usable solution in the next phase. Furthermore, in the communications field, the increase in data volume has led to a global issue of increasing power consumption in data center and other facilities. The IOWN concept proposed by NTT emphasizes the importance of photonics-electronics convergence in realizing an all-photonics network, which is the key to achieving ultra-low power consumption. As optical connection technology is essential in this field, policy to focus on working towards its realization in collaboration with IOWN.

Fusion energy (fusion energy power generation), which is expected to be the next generation of energy, is attracting attention as a clean energy source that does not emit CO2. However, the technical hurdles are still high, and it will take time to put them into practical use. Fujikura's high-temperature superconducting wires are expected to be the key to the practical application of fusion energy, and are expected to be used as coil materials for controlling strong magnetic fields. For this reason, Fujikura believes that it is important to collaborate with government agencies and research institutes in various countries, as well as Kyoto Fusion Engineering, a venture from Kyoto University, to consider what Fujikura can do for the early practical application of fusion energy.

In the third area, millimeter wave applications, we are working on two R&D themes: the 28 GHz band for 5G and the 60 GHz band for industrial applications. The 28 GHz band has been slow to spread due to some difficulties in its use, but technical standards are being developed to resolve this. We are working on technology and product development to quickly introduce products in this conformity band. The 60 GHz band, on the other hand, is promising as a remote monitoring solution due to its characteristics of enabling license-free, low-latency, high-definition video transmission. We see this as one direction, and are participating in NTT's IOWN initiative to promote research and development for practical applications.

In such advanced research and development, open innovation initiatives are effective. For example, in the research and development of next-generation optical communications, core technologies related to light are developed at Fujikura, and peripheral technologies and their applications are being accelerated by collaborating with several U.S. universities. In addition, it is the responsibility of companies to work towards carbon neutrality in response to the recent issue of global warming. In addition to reducing the amount of CO2 emitted by Fujikura's business activities, we believe that it is also important to reduce CO2 emissions by allowing our customers to use Fujikura's technology. For example, if fusion energy can be realized, in extreme cases, CO2 emissions will be zero. In other words, Fujikura's high-temperature superconducting wire materials can be the key to contributing to the practical application of fusion energy that does not emit CO2. Fujikura can contribute to society in this way, so I would like to actively promote R&D activities from that perspective.