Technology Areas/Product Groups

High-Temperature Superconductor

High-temperature superconductivity technology is expected to contribute significantly to the realization of a carbon-neutral society in various fields due to its wide range of applications. Especially in the energy field, power generation using fusion energy (fusion energy power generation) is growing as one of the future power generation methods.

Compared to conventional energy, fusion energy does not emit carbon dioxide during its power generation process, and its resources are abundant in seawater. In addition, because it does not overheat, it is said to be excellent in terms of safety and other aspects, and is expected to be a technology that fundamentally solves energy and environmental problems.

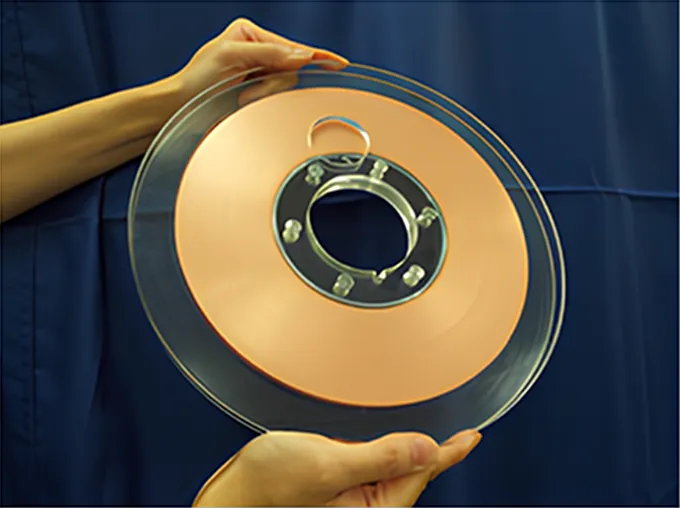

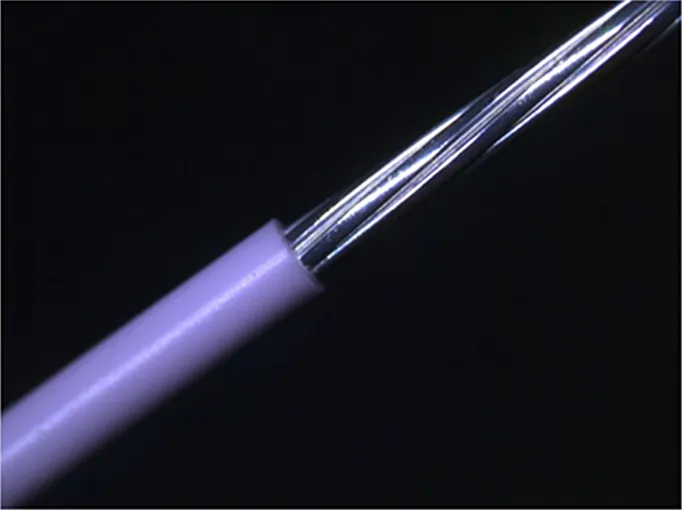

In recent years, there has been a movement to accelerate the practical application of fusion energy by adopting rare earth high-temperature superconducting wires to reduce the size of superconducting magnets required for fusion energy than before. Fujikura continues to conduct world-class research and development, and provides high-performance, uniform rare earth high-temperature superconducting wires both domestically and internationally, earning high praise from users.

Fujikura aims to realize a carbon-neutral society by contributing to the development of fusion energy, and at the same time contributes to the development of various next-generation superconducting equipment, such as electric aircraft and analytical instruments.

Fiber Laser

Fujikura's high-power continuous wave multi-mode fiber lasers (Figure 1) are used for cutting and welding metals, while continuous wave single-mode fiber lasers with excellent beam quality are used for joining different materials and cutting carbon fiber reinforced plastics (CFRP). Q-switched pulsed fiber lasers are used for marking and metal processing, and MOPA pulsed fiber lasers (Figure 2) are used for micromachining of various materials.

As such, fiber lasers are used for processing in a wide range of fields, and their applications are expanding to include biotechnology, medicine, battery and semiconductor manufacturing, etc. To meet these market demands, Fujikura is realizing new processing by continuing to develop the elemental technologies that make up fiber lasers (high-power laser diodes, rare-earth doped and special optical fibers, fiber-type optical components, etc.).

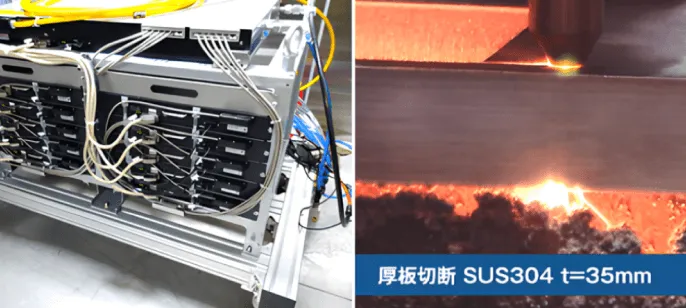

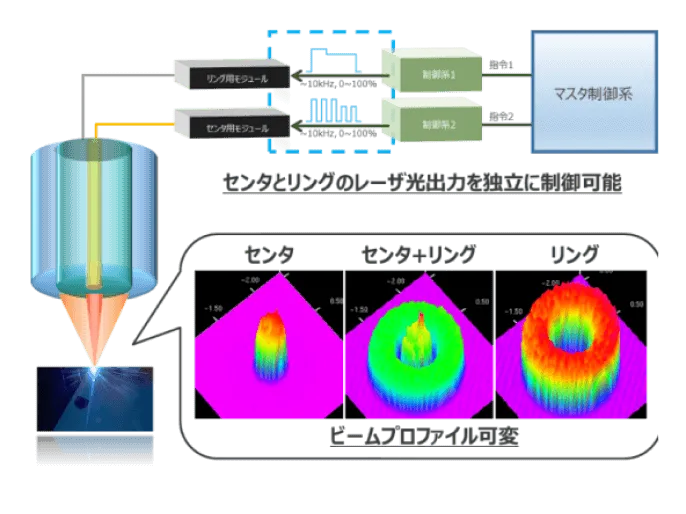

Recently, we have been developing and commercializing technologies such as a 20 kW ultra-high-power continuous wave multi-fiber laser for high-speed cutting of thick metal plates (Fig. 3), a beam profile variable technology that improves processing quality by controlling the laser beam shape (Fig. 4), and a wavelength conversion technology that improves processing speed by converting the wavelength of light that is likely to cause deterioration of the processed material.

Another promising future application for fiber lasers is wireless energy transmission using laser light. This is called a "Space Solar Power System (SSPS)," in which solar energy in space is transmitted to Earth using laser light, and then converted into electricity on the ground. Research and development into this system is being carried out by many organizations.

We will continue to research and develop fiber laser products and technologies to meet customer needs. We will not only realize a wide variety of high-performance, high-quality processing, but also contribute to society by reducing environmental impact through high efficiency and energy savings.

Conductor/Insulation

The conductor and insulating material technologies cultivated over a long history of product development related to energy and information transmission have provided a powerful boost to the Fujikura Group’s manufacturing. In recent years, regarding conductors for wire harnesses that contribute to reducing the weight of automobiles, we have developed an aluminum alloy conductor that combines high strength, high conductivity, and high ductility by controlling the metal microstructure through consistent development from alloy composition to processing.

By reducing the weight of resins used in the coating materials for electric wires and cables, we are reducing the energy consumption when installed in automobiles and contributing to the achievement of the SDGs. In addition, by replacing flammable resin materials with flame-retardant materials that are gentle on the human body and the environment, we have provided safety and security to our customers. We will continue to support Fujikura Group’s products and manufacturing through our core material technologies.

Heat Transport Devices

Power semiconductor cooling module

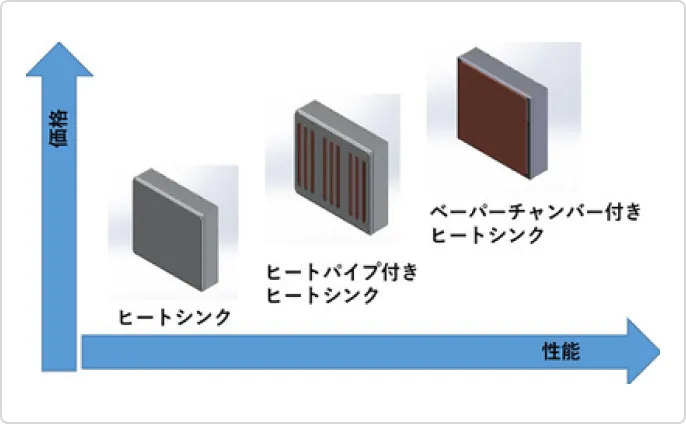

We are developing large-capacity heat pipes and vapor chambers to dissipate heat from power semiconductors that generate large amounts of heat. Vapor chambers are flat heat pipes that have high heat dissipation performance because the entire surface acts as a heat pipe. We are also working on improving the internal structure to increase maximum heat transport capacity and reduce thermal resistance.

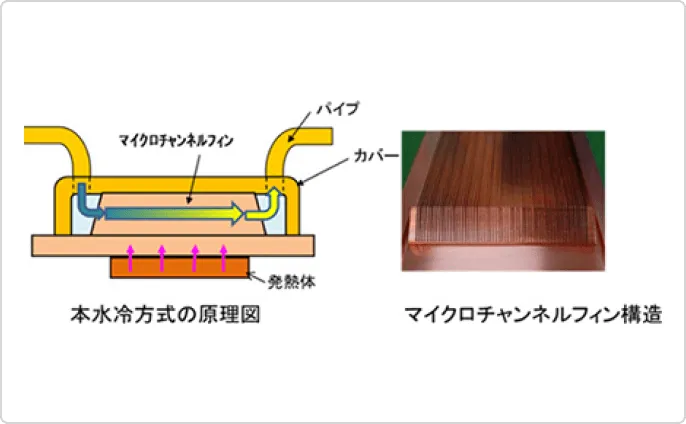

Cold plate for high performance computer

We have developed a liquid cooling unit called a cold plate, which uses a microchannel fin structure (fin thickness: 0.15 to 0.4 mm) to dissipate heat from large computers such as supercomputers and mainframes. This cold plate requires less space than air-cooled systems, yet provides several times more cooling performance.

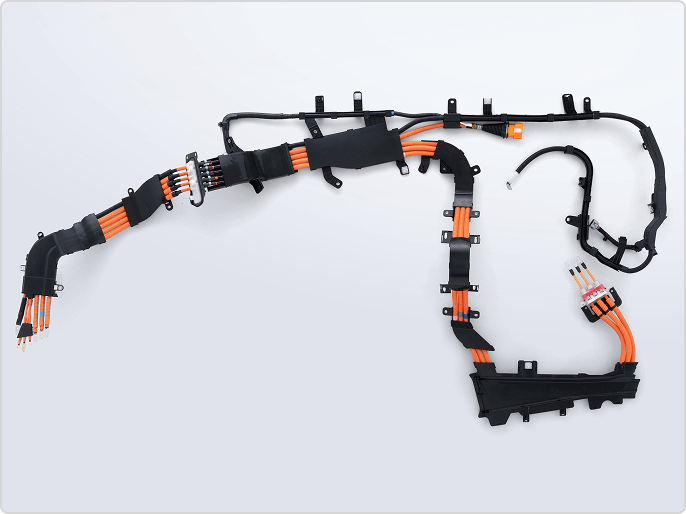

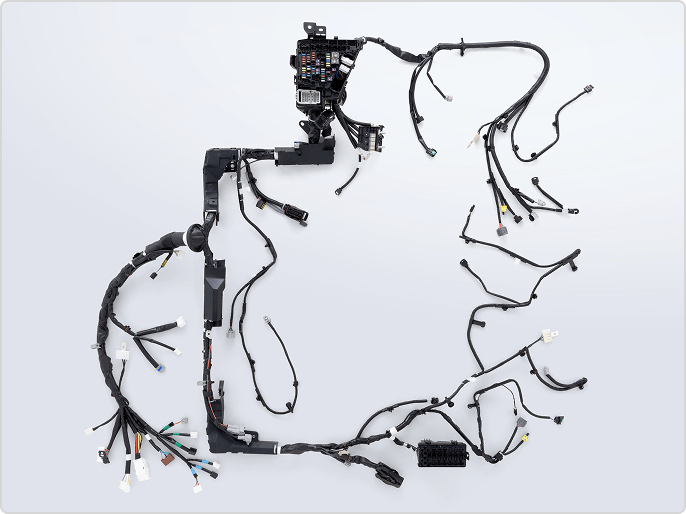

Wire Harness

Wire harness, which are often referred to as the "nerves and blood vessels of a car," are bundles of wires that act as electrical pathways to ensure the proper operation of electronic units inside the car, connecting power and signals to every corner of the car.

With the increasing electronics content of in-vehicle equipment every year, Wire harness are becoming more complex.

Fujikura utilizes the latest technology and the wisdom and experience it has cultivated over many years to comprehensively develop and manufacturing Wire harness, from wiring materials and in-vehicle wiring systems to fuse boxes, connectors, and terminals.

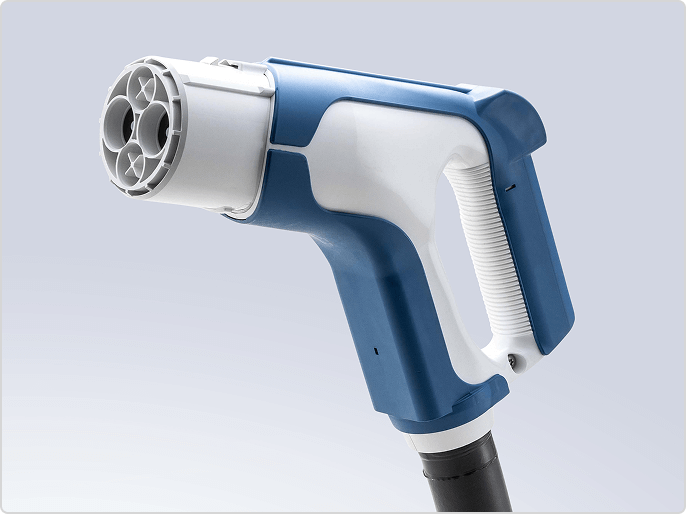

High Current Connection

Reducing charging time is one of the challenges facing the widespread adoption of electric vehicles (EVs). Reducing charging time requires increasing the charging current, but this poses the problem of increased heat generation within the charging cable connector. Increasing the cable conductor size reduces heat generation, but this makes the cable heavier and larger, reducing ease of use during charging. To increase charging current without increasing the cable conductor size, we developed a liquid-cooled cable connector that employs liquid cooling technology to circulate a liquid refrigerant within the cable connector to efficiently remove heat. This technology enables a rated charging current more than three times higher than conventional models, while maintaining weight and size without compromising operability.