Technology Areas/Product Groups

Optical Connector

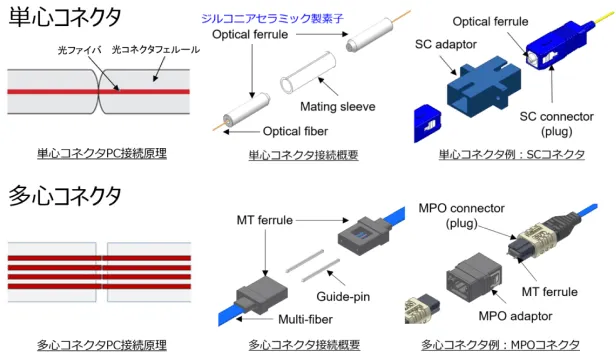

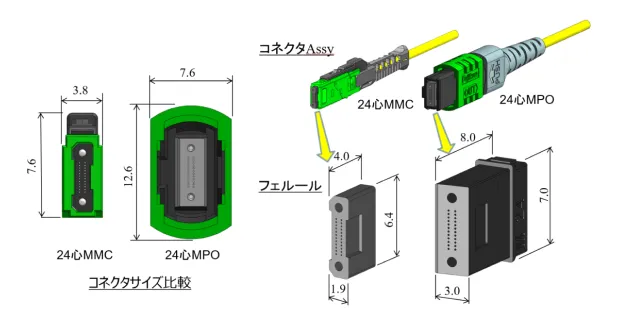

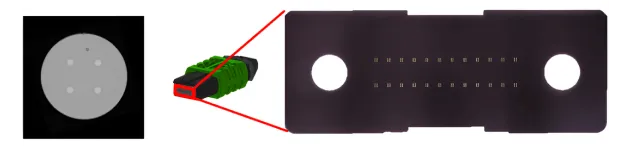

Optical connectors precisely align Optical Fiber and bring their end faces into close proximity or contact, achieving low-loss, highly reliable, repeatable connections. They are application in single-fiber and multi-fiber connectors (Figure 1), each with multiple connection methods. Fujikura possesses core technologies in each connection method and offers a variety of solutions tailored to customer applications. PC connection physically connects the end faces Optical Fiber. Fujikura has been developing low-loss and multi-fiber optical connectors using high-precision polishing and precision resin molding technologies. In addition to PC connection, we also offer field-assembled optical connector solutions (Figure 2) that combine refractive index matching materials and Fusion Splicer. In recent years, the increasing data traffic volume in hyperscale data center (HSDCs) has led to increased demand for high-density optical connectors and optical wiring solutions. To address this challenge, Fujikura is expanding into this new field with its compact, high-density MMC ferrule connectors (Figure 3), a key component, and wiring solutions. In addition, we are developing products compatible with 80 μm clad Optical Fiber, which will enable even smaller size and higher density. To achieve even higher density, we are also working on developing a multi-core optical connector, the MCF-MPO connector (Figure 4), which assembles multi-core fibers with multiple cores in a single fiber.

Figure 1: Single-fiber connector and multi-fiber bulk connector

Figure 2: Examples of field-assembled connectors (Left: fusion-type MPO connector, Right: refractive index-matched single-fiber connector)

Figure 3: MMC vs MPO connector comparison

Figure 4: Multicore fiber (left) and MCF-MPO connector (right)

Fusion Splicer

Fujikura is currently researching and developing an optical fiber fusion splicer. These devices measure the positon of the core of an optical fiber with high precision and align two optical fibers at the submicron level using a precision axis alignment mechanism. Fusion splicing is then performed using either quasi-corona discharge or CO2 lasers. Quasi-corona discharge fusion splicers using tungsten electrodes are compact and are primarily used to connect optical fibers for communication. On the other hand, CO2 laser-based fusion splicers are primarily used to process specialty optical fibers because tungsten does not adhere to the optical fibers. The properties of CO2 lasers are utilized not only for splicing, but also for processing tip lenses and fabricating optical couplers. This device utilizes mechatronics technology and has established a leading position in the global market.

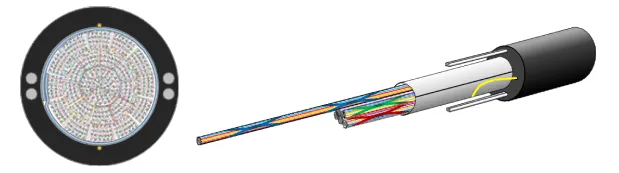

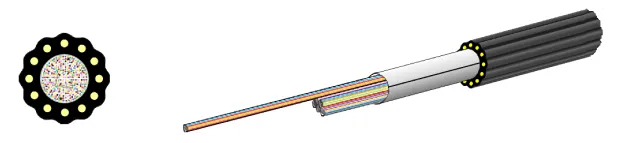

High-density Fiber Optic Cable

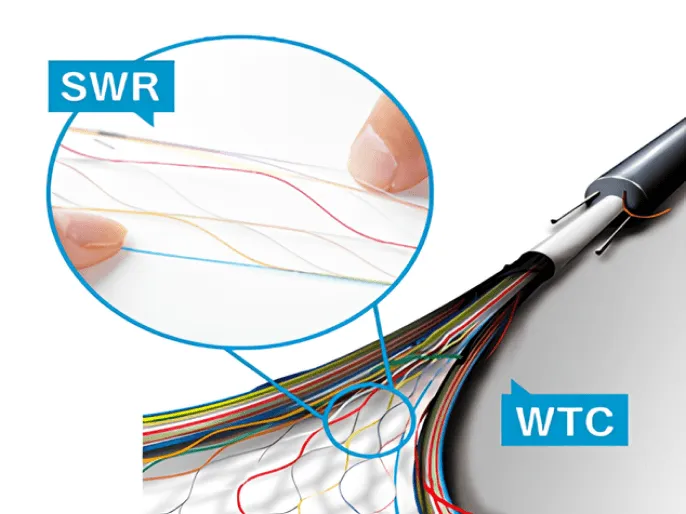

- ①Increased the number of laying in existing conduits while still using the existing laying method

- ②Shortened splicing time by using SWR® to splice ribbons together

- ③Reduced connection points by laying in a single line from outdoors to inside the premises

Ultra-thin high-density WTC®

Air-blown WTC® (AB-WTC™)

Electric Connectors

For over 60 years, Fujikura has been developing, manufacturing, quality control (QC) and sales original connectors.

In recent years, there has been an increasing demand for smaller and lighter mobile devices, including smartphones, and connectors are also being required to be "ultra-low profile," "ultra-compact," and "highly easy to mate."

To meet these market needs, Fujikura is working to develop connectors that are both compact, lightweight, and multifunctional.

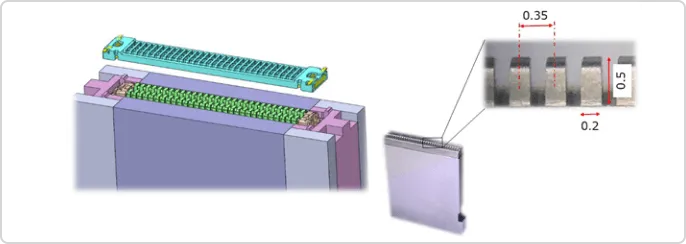

To meet these ever-increasing demands, we will continue to hone the following technologies and develop the world's top-level ultra-miniature connectors.

Design Technology

- Structural analysis technology developed over many years to ensure contact reliability

- Flow analysis technology that allows resin to be filled even in thin walls (FTTH)

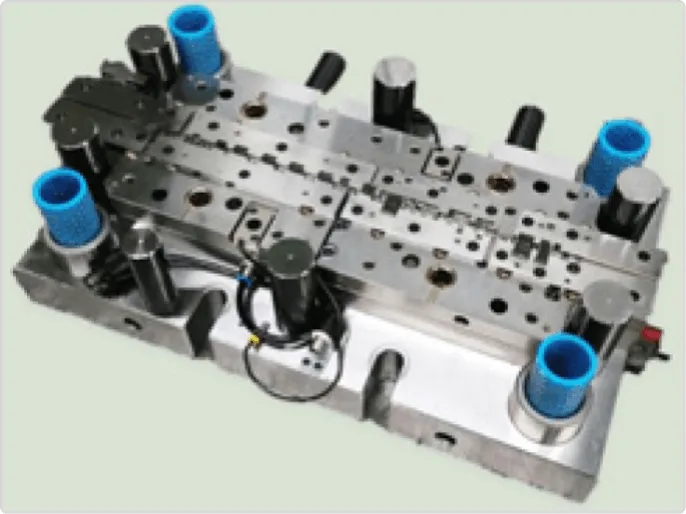

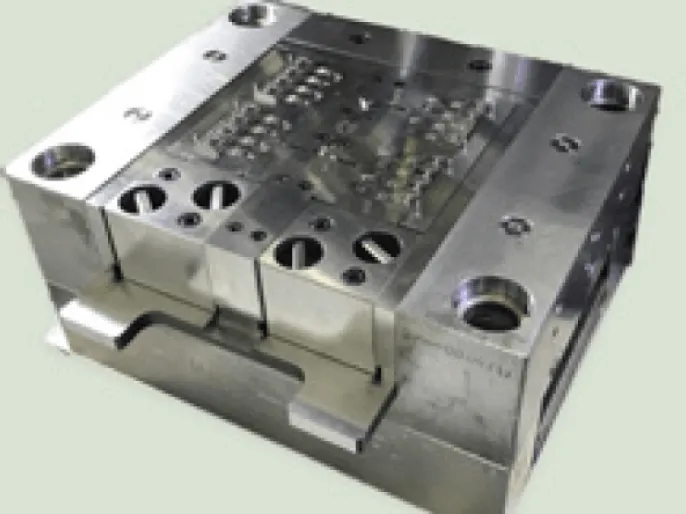

Production Engineering

- Press die manufacturing technology, press processing technology

- Resin molding die manufacturing technology, thin-walled resin molding technology

- High-speed automatic inspection, assembly, and packaging technology

- Gold-saving plating technology for ultra-small terminals

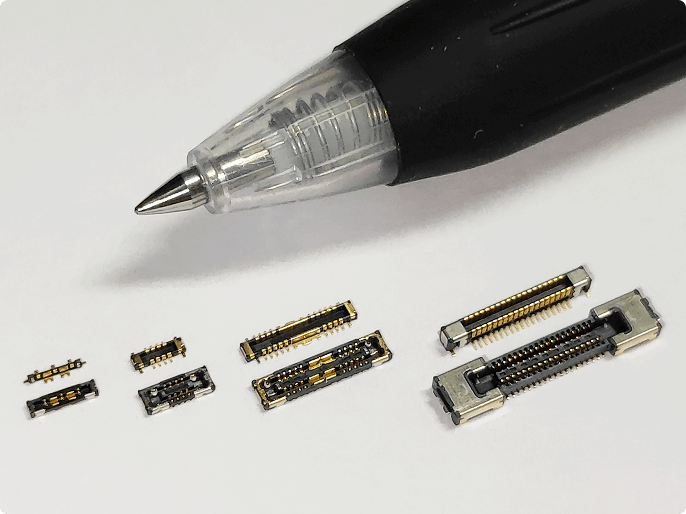

Board-to-board connector (FB3A series)

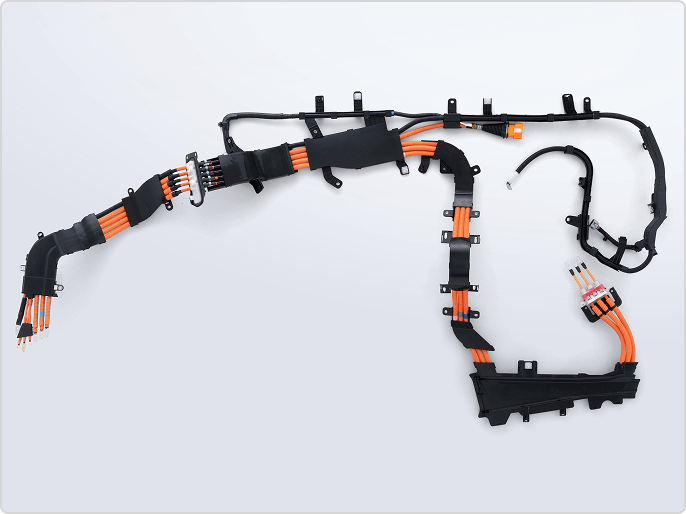

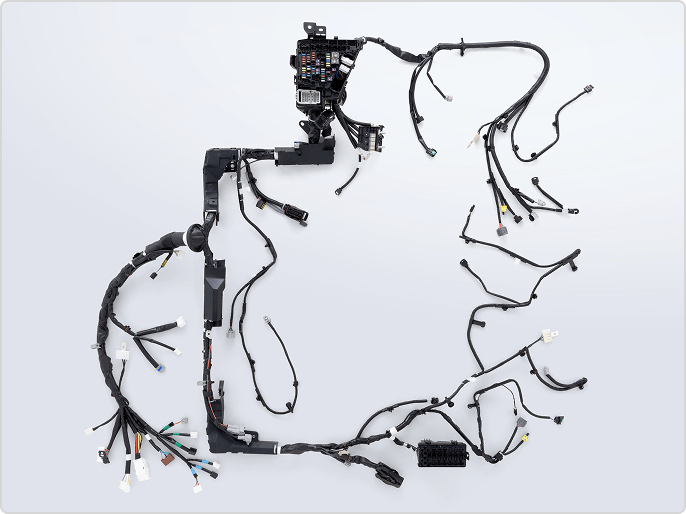

Wire Harness

Wire harness, which are often referred to as the "nerves and blood vessels of a car," are bundles of wires that act as electrical pathways to ensure the proper operation of electronic units inside the car, connecting power and signals to every corner of the car.

With the increasing electronics content of in-vehicle equipment every year, Wire harness are becoming more complex.

Fujikura utilizes the latest technology and the wisdom and experience it has cultivated over many years to comprehensively develop and manufacturing Wire harness, from wiring materials and in-vehicle wiring systems to fuse boxes, connectors, and terminals.

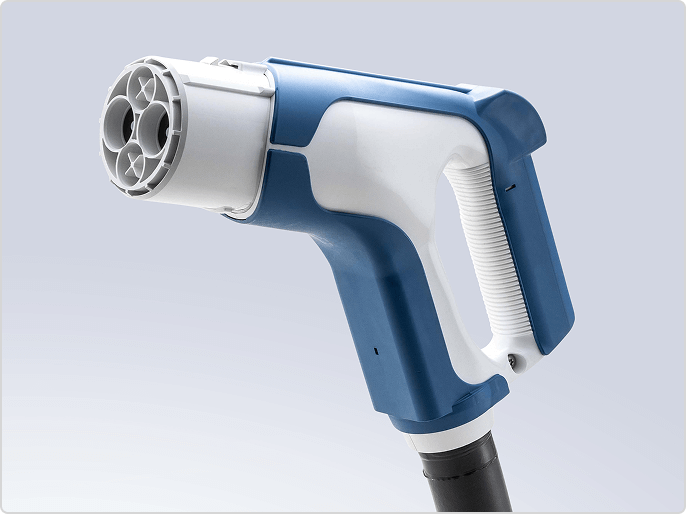

High Current Connection

Reducing charging time is one of the challenges facing the widespread adoption of electric vehicles (EVs). Reducing charging time requires increasing the charging current, but this poses the problem of increased heat generation within the charging cable connector. Increasing the cable conductor size reduces heat generation, but this makes the cable heavier and larger, reducing ease of use during charging. To increase charging current without increasing the cable conductor size, we developed a liquid-cooled cable connector that employs liquid cooling technology to circulate a liquid refrigerant within the cable connector to efficiently remove heat. This technology enables a rated charging current more than three times higher than conventional models, while maintaining weight and size without compromising operability.