Environment

Society

Human capital

- Human Rights

- Development of Human Resource

- Development of Global Human Resource

- Diverse Human Resource and Diverse Working Styles

- Health Management to Enhance Corporate Value

- Occupational Safety and Health

- Occupational Safety and Health

- Business Continuity

- Business Continuity Plan/Management (BCP/BCM)

- Communication

- Procurement Activities

- Stakeholder Engagement

- Social Contribution Activities

Governance

Technological Strengths

[Environmental policy] Global Environmental Charter

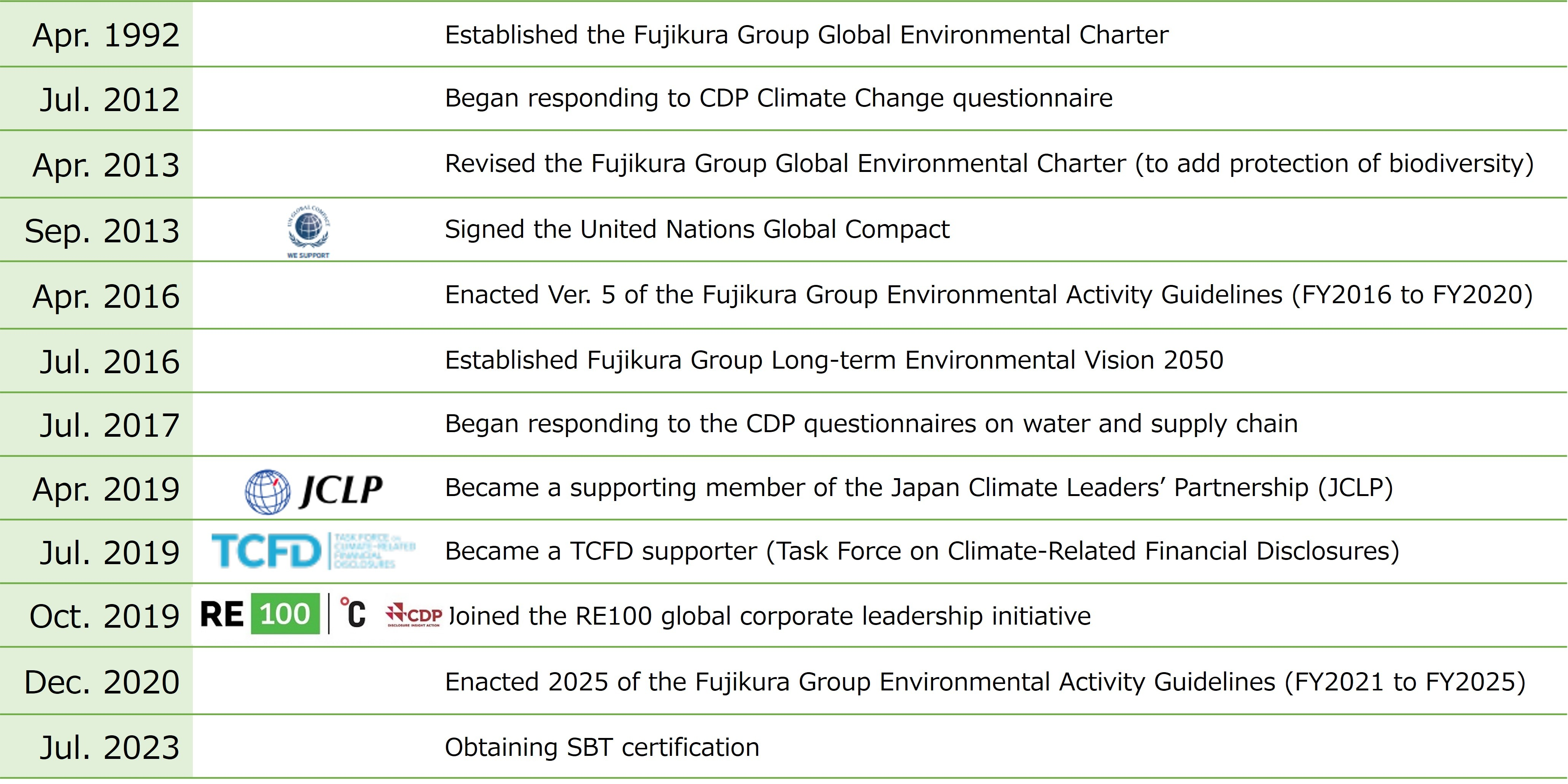

Fujikura Group establishment the Fujikura Group Global Environmental Charter in 1992, and added "biodiversity conservation" as one of its important environmental themes in 2013.

Fujikura Group Global Environment Charter

establishment April 1992 / revision November 2020

Preamble

Human civilization has made great strides with the rapid development of science and technology, allowing us to enjoy affluent lives. However, at the same time, environmental destruction is progressing on a global scale, with issues such as global warming, ozone layer destruction, acid rain, tropical forest reduction, desertification, and marine pollution, and serious situations are developing that threaten not only the survival of humanity but also of all life on Earth. These global environmental issues are deeply related to complex and diverse social systems, and it cannot be denied that corporate activities are one of the major factors. Fujikura Group is deeply aware that our business activities are closely related to the global environment, and will make every effort to protect the global environment.

Basic Philosophy

Fujikura has expanded its basic policy of "ensuring a rich and bright life through the efforts of all Fujikura Group to a global scale, and the entire company is committed to protecting the global environment as one of its most important management priorities.

guideline Conduct

In all areas of our corporate activities, each and every one of us will prioritize the conservation of the global environment.

1. organization and Management

We will establish an internal organization and operating system for environmental conservation, with the Director in charge of the environment as the person in charge, and each organization will clarify its environmental goals and promote planned and continuous improvement.

2. Improving environmental management standards and levels

In addition to complying with national and local environmental regulations, we will set our own management standards and strive to further improve our level of environmental management. We will also regularly conduct environmental audits to maintain and improve our own management.

3. In business activities

We strive to protect the environment at all stages of our business activities, from product development, design, purchasing, production, construction, sales, Butsuryu, disposal, etc. Furthermore, we strive to prevent environmental pollution by conserving energy and resources, promoting recycling, and reducing disposal and environmentally hazardous substances.

4. Providing appropriate information to customer

Provide product users with information on proper usage, recycling, and disposal methods.

5. Contribution to the local community

We will actively participate in local environmental conservation activities, strive to strengthen mutual understanding and cooperative relationships, and contribute as a member of the local community.

6. Overseas business activities

We will of course comply with the environmental standards of the countries in which we operate, but will also set our own voluntary management standards and strive to protect the environment. Furthermore, we will proactively utilize technology and know-how for environmental protection, and strive to develop human resources in environmental management.

7. publicity and awareness activities

We will provide education, publicity and awareness-raising activities to all employees to improve their understanding of global environmental conservation and environmental awareness.

8. Biodiversity Conservation

We recognize the importance of biodiversity in the global environment and strive to conserve ecosystems.

[Long-term goal] Fujikura Group Long-term Environmental Vision 2050

Fujikura Group established its Long-Term Environmental Vision 2050 in 2016, taking into account the adoption of the Paris Agreement at the 21st Conference of the Parties to the United Nations Framework Convention on Climate Change (COP21) in 2015, and the goal of reducing CO₂ emissions by 80% by 2050 (compared to 2015) in the Global Warming Countermeasures Plan establishment in March 2016.

Fujikura Group Long-Term Environmental Vision 2050

establishment on July 19, 2016

Preamble

Since its founding in 1885, Fujikura Group has been contributing to society and creating value for customer through "Tsunagu" technologies, such as electric wires and cables, electronic wiring components, and automotive electrical components. In addition, since 2009, as a corporate group that is friendly to people and the global environment, we have been working on "corporate social responsibility" (CSR) initiatives to realize a sustainable society.

According to predictions by international organizations such as the Organization for Economic Cooperation and Development (OECD), the global environment is now heading toward a critical situation. Extreme weather caused by climate change due to greenhouse gases is threatening our daily lives, and environmental problems such as water shortages, resource depletion, serious air pollution, and the deterioration of biodiversity, which have become widespread and are becoming more serious on a global scale, along with population growth and increased economic activity.

In light of this current situation, Fujikura Group, which conducts business globally, will, as a global citizen, look ahead to the future in 2050 and tackle "four challenges" to minimize its environmental impact.

Furthermore, by 2065, when we will mark our "fourth founding," we will continue to reduce the Group's environmental impact and take on the challenge of reducing our burden on the global environment from zero to even negative (having a positive effect on the global environment).

"Four Challenges" Goals and Main Activities for 2050

[Challenge 1] Zero CO₂ emissions at plant by 2050

We aim to reduce our CO₂ emissions by 2030 by an amount that surpasses the level required of the industry by the government (versus FY2013).

- [Major Activities]

- ① Improve environmental performance of products

- ② Use renewable energies

- ③ Employ hydrogen energy

- These are Fujikura's three pillars for reducing CO₂ emissions

[Challenge 2] Minimize use of water at plants and wastewater management

-Do not use, reuse, and return to nature clean-

- [Major Activities]

- ① Minimize water use during the production process and reuse water

- ② Recycle plant wastewater, including the use of rainwater

- ③ Treat wastewater to a level of quality that is safe and sufficient for its return to nature, etc.

[Challenge 3] Symbiosis between plant workers and nature

- [Major Activities]

- ① Enrich and use the Millennium Woods biotope garden at Fujikura sites around the world

- ② Promote regional activities to preserve the natural environment

- ③ Promote natural environment education for future generations, etc.

[Challenge 4] Effective use of resources and resource cycle ⇔ Depletion of resources and increased waste

- [Major Activities]

- ① Use eco-materials

- ② Environmentally-friendly and long-life product manufacturing

- ③ Develop recycling technologies, etc.

The challenge towards our fourth founding (2065)

By 2065, when we will celebrate our "Fourth Founding," Fujikura Group will continue to reduce its environmental impact, taking on the challenge of reducing its environmental impact from zero to even negative (having a positive effect on the global environment).

![[Long-term goal] Fujikura Group Long-term Environmental Vision 2050](https://data.wovn.io/ImageValue/production/67aeec2a091dbe008a477fe4/en/40ff10636a59e81f3f5f2af2a7bbc24c/en2024_2-3-climatechange2050_1.jpg)

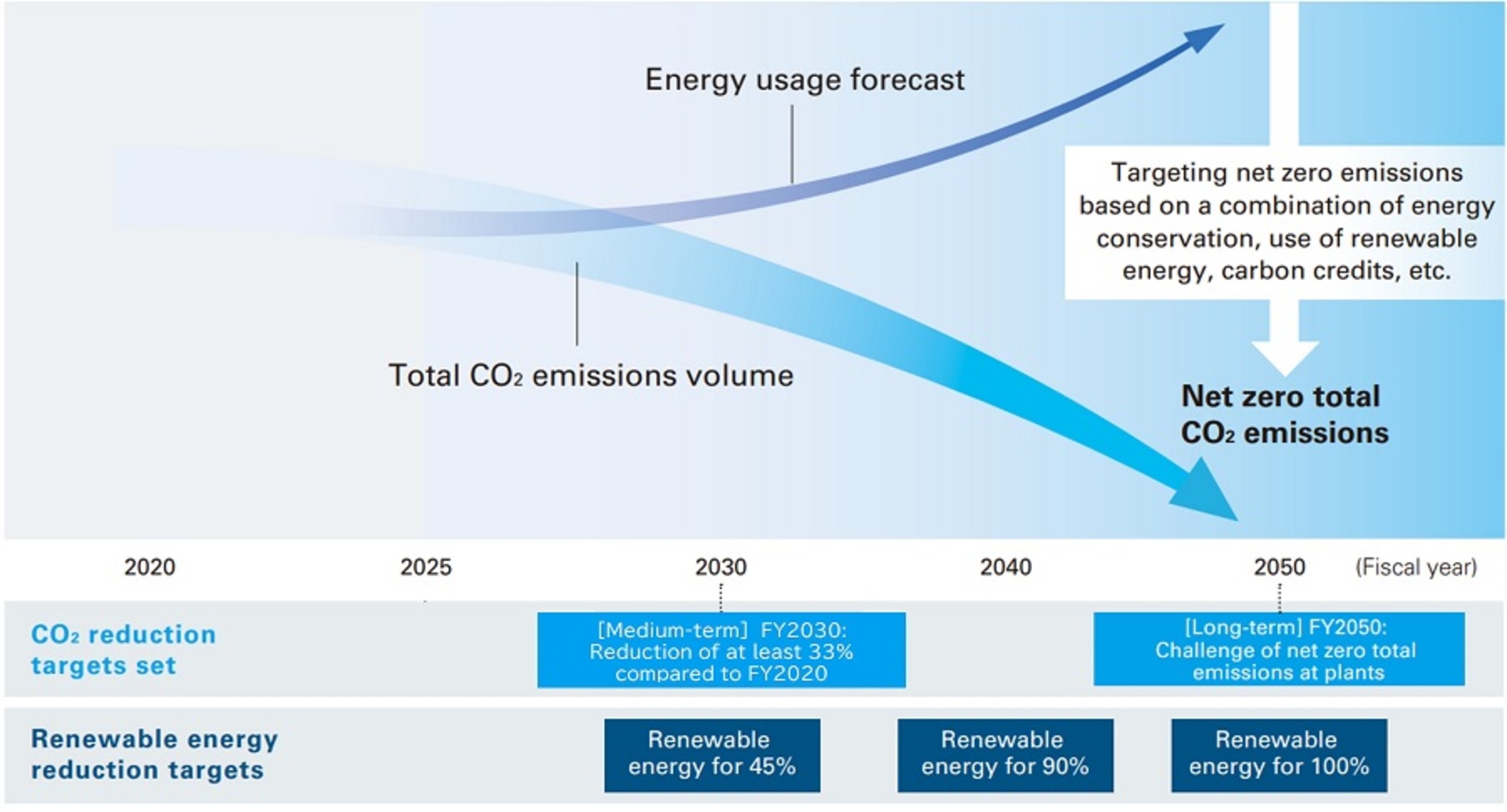

Roadmap to Zero CO₂ Emissions

Under the Fujikura Group Long-Term Environmental Vision 2050, one of our key challenges is to “challenge ourselves to achieve zero CO₂ emissions from our factories by 2050.” Toward achieving this target, we have established the following roadmap for reducing CO₂ emissions. We will promote specific measures, such as energy conservation, the introduction of renewable energy, and the purchasing of environmental value.

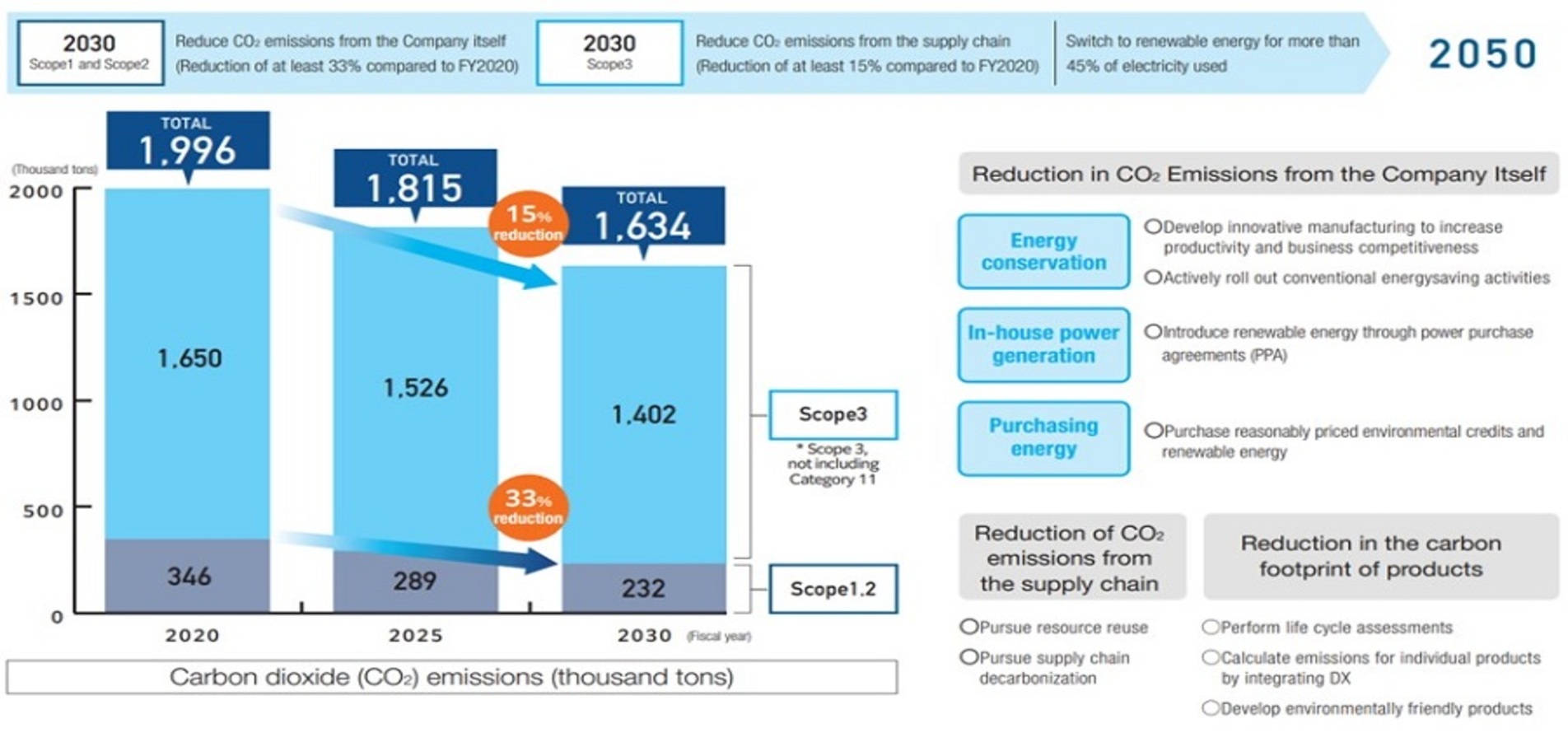

Setting CO₂ Reduction Targets

- FY2030: Reduction of 33% or more compared to FY2020

- FY2050: Challenge to achieve zero emissions from factories

Promotion System

To share these goals and promote related activities, the Fujikura Group Global Environment Committee, which is a committee attended by the director in charge and representatives from all business units and major sites, meets every other month to check consistency with the activities of each unit, review plans as necessary, and promote climate change countermeasures.

Fujikura Group's Progress in Climate Change Countermeasures

Third-party Verification of Environmental Performance Data

To enhance the reliability of disclosed data, the Fujikura Group conducts annual verification of its environmental performance data by an independent third party.

Environmental performance data can be found here

Response to CDP

The Fujikura Group has been responding to CDP since 2012. Please click here to view the latest score.

Commitment to Industry Guidelines

Fujikura is a member of the Japan Electric Wire & Cable Makers’ Association (JECA), an organization representing electric wire and cable manufacturing businesses in Japan.The Association is working on a “Voluntary Action Plan for Environmental Conservation” in order to contribute to the achievement of the “Action Plan for a Low-Carbon Society” promoted by the Ministry of Economy, Trade and Industry and the Japan Business Federation.

To address environmental issues specific to the electric wire industry, such as climate change countermeasures and disposal reduction, the Association has an organization in the form of an environmental subject matter committee. Regarding climate change countermeasures, the committee has set medium- to long-term targets, including a target for 2030, focused primarily on reducing energy consumption related to the manufacturing of metal cables and optical cables. These targets are incorporated into the environmental goals of each company.

In addition, with the aim of creating a recycling-oriented society, efforts are being made to promote the recycling of industrial disposal.

Participating in Sustainability Initiatives

As part of the Fujikura Group’s strategy, in addition to the above goals, we have joined RE100, declared our support for the TCFD, and obtained SBT certification.

e joined RE100 in 2019 and aim to source 100% of the electricity required for our business activities from renewable energy. We have set a target of achieving 100% renewable electricity by 2050, with mid-term targets of 45% by 2030 and 90% by 2040.

In addition, we obtained SBT certification in July 2023. To achieve carbon neutrality, we will promote initiatives across our own operations and the Fujikura Group as a whole, while also advancing efforts throughout our supply chain.

Learn more

Learn more