- HOME

- Products

- Fiber Laser

- Fiber Laser

- CW single mode fiber laser product range

CW single mode fiber laser product range

strong point / feature

- Single mode: long feed fiber

- Major optical components are developed and manufactured in-house

- Our unique fiber design enables direct irradiation

- Stimulated Raman scattering is suppressed to achieve stable laser processing.

Application Examples

- Micro welding of electronic components and connector parts

- Welding of thin metals and non-metals

- CFRP cutting

- Metal foil cutting

- Metal Additive Manufacturing

- Processing of highly reflective materials (copper, aluminum)

- Spatter-free high-quality welding (wobbling welding)

- Surface Treatment

Case study (Joining of dissimilar materials by welding)

Fujikura has developed a dissimilar material joining technology that directly welds the copper foil and aluminum material of FPCs (Flexible Printed Circuits). In general, when welding copper and aluminum, brittle intermetallic compounds are formed at the joint, reducing the joint strength and making it difficult to application. To solve this problem, we have used a fiber laser and a unique welding method that enables joining with reduced intermetallic compound formation. We aim to application this dissimilar material joining technology in high current applications, where the aluminum reinforcing plate, which is commonly used as a reinforcing plate for FPCs, is used as a current path.

Model

*Some models are subject to export restrictions under the Foreign Exchange and Foreign Trade Act.

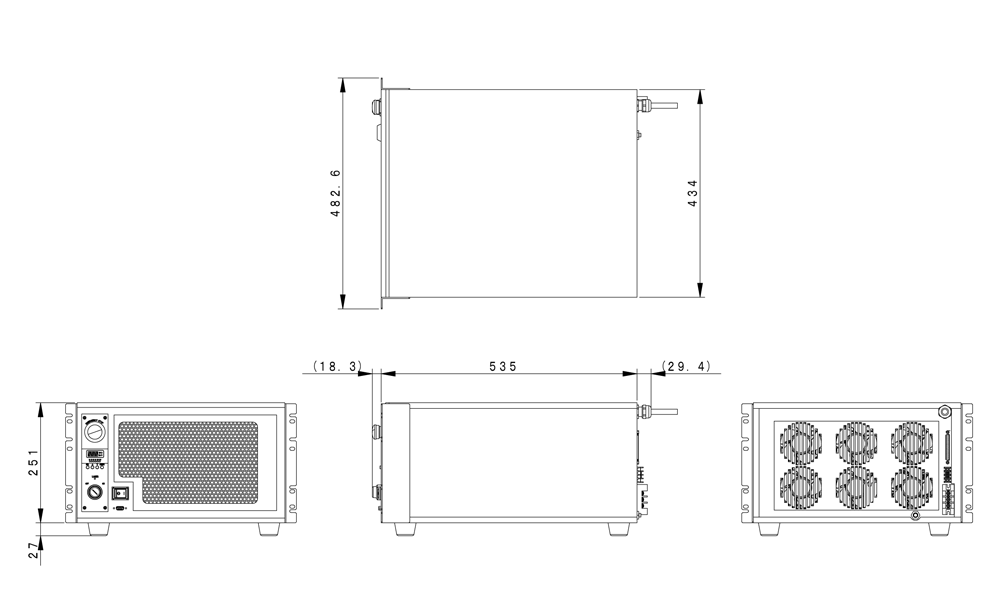

Product Appearance

Other products in this category

Product finder

- HOME

- Products

- Fiber Laser

- Fiber Laser

- CW single mode fiber laser product range