Back to list

Press Releases

sales of "Single Jacket Single Armor WTC™" commenced

September 9, 2024

Fujikura Ltd.

Fujikura Ltd. (Director, President and CEO: Okada Naoki) has developed and begun sales a new Fiber Optic Cable, "Single Jacket Single Armor WTC™ (hereinafter SJSA-WTC™)."

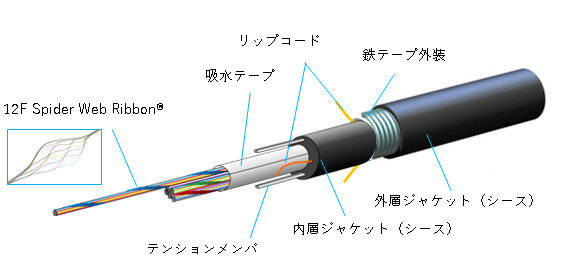

The new product SJSA-WTC™ is a cable that houses Optical Fiber ribbon SWR® *1, which enables bulk fusion splicing, in Fujikura proprietary wrapping tube structure (Wrapping Tube Cable®: WTC® *2). By combining the two-layer jacket (sheath) that previously sandwiched the iron tape exterior (armor) into a single layer, we have achieved a cross-sectional area that is approximately 31% thinner and approximately 25% lighter than conventional products.

|

|

Figure 1. New product "SJSA-WTC™"

~Key Points~

・By adopting a single-layer jacket structure, the conventional WTC ® Approximately 31% smaller cross-sectional area compared to

・By eliminating the inner jacket, the mass of materials has been reduced by approximately 25%, reducing the environmental impact

・Optimized design achieves tensile and bending strength equivalent to conventional WTC®

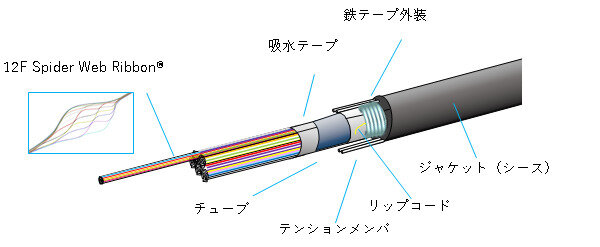

SJSA-WTC™ uses a single layer jacket structure.

By reviewing the conventional double-layer sheath structure (double jacket single armor), in which an inner jacket is covered with an outer jacket (sheath) with an iron tape exterior (armor), we have created a world-class thin and lightweight Fiber Optic Cable.

By reviewing the conventional double-layer sheath structure (double jacket single armor), in which an inner jacket is covered with an outer jacket (sheath) with an iron tape exterior (armor), we have created a world-class thin and lightweight Fiber Optic Cable.

In addition, the design has been optimized to achieve high density without compromising the necessary mechanical strength (tensile strength, bending strength, etc.).

This means that it can be used without problems in laying applications that require mechanical strength, such as along railway tracks, directly buried underground, and in rural and underground areas where there is a risk of bird and animal damage. In addition, the workability when removing Optical Fiber from the cable has been greatly improved compared to the conventional double-sheathed WTC®.

|

|

Figure 2. Structure of SJSA-WTC™

|

|

Figure 3. Traditional WTC® structure

Comparison of the structure of conventional WTC® and SJSA-WTC™

While the volume of communication data continues to increase, the space available laying cables in urban areas is becoming saturated.

The adoption of SJSA-WTC™ will enable more efficient construction of networks that utilize underground areas in urban areas and rail networks connecting cities, contributing to the expansion and improvement of telecommunications services in rural areas.

Going forward, Fujikura will continue to develop high-quality, innovative products that will contribute to the construction of high-density communication networks in a variety of environments while also helping to reduce the burden on the environment.

*Spider Web Ribbon® (SWR®), Wrapping Tube Cable® (WTC®), Single Jacket Single Armor WTC™, and SJSA-WTC™ are registered trademarks or trademarks of our company.

*1 Spider Web Ribbon® (SWR®)

Optical Fiber ribbon developed using Fujikura proprietary technology. It is made by intermittently bonding single-core fibers and is aspect by its flexibility. It enables high-density mounting within the cable, contributing to the creation of thinner and higher-density Fiber Optic Cable.

*2 Wrapping Tube Cable® (WTC®)

This is the name of a small-diameter, high-density Fiber Optic Cable that incorporates SWR® and was developed using Fujikura proprietary technology. It is an optical cable with a simple structure in which Optical Fiber ribbon is covered with a pressure-wrapped tape. Since it has a smaller diameter and higher density structure than conventional Fiber Optic Cable, such as the slot structure that is mainly used in Japan and the loose tube structure that is common overseas, it can use existing conduits and significantly shorten the construction period.