Press Releases

sales of new clad fusion splicer commenced

July 11, 2023

Fujikura Ltd.

Fujikura Ltd. (Director, President and CEO: Okada Naoki) has developed a new clad aligning fusion splicer, the 45S, and will begin sales in August.

|

|

By using this product in combination with the included single-core stripper "SS05" and Optical Fiber cleaver "CT50", the time required for Optical Fiber fusion splicing work has been reduced by 30% *1 compared to conventional machines.

【point】

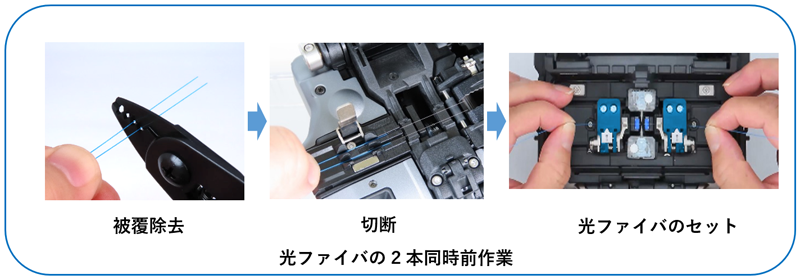

- Improved pre-processing of two Optical Fiber required before fusion splicing can now be performed simultaneously on two optical fibers in one operation, reducing fusion splicing work time by 30% compared to previous models

- Improved usability with monitor angle adjustment function, removable battery, expansion tray, etc.

・Improves the efficiency of fusion splicing work, helping to alleviate labor shortages at work sites

Fusion splicing of Optical Fiber requires the prior steps of stripping the coating from Optical Fiber, cutting them, and loading them into the fusion splicer. Conventionally, to fusion splice two Optical Fiber, each step had to be performed one by one.

The single-core stripper for removing the coating has a blade structure that allows it to simultaneously remove the coating from two Optical Fiber cleaver for cutting has a structure that allows it to fix two Optical Fiber and cut them simultaneously.

Furthermore, when attempting to set two Optical Fiber on the left and right sides of the fusion splicer at the same time, Optical Fiber are held in each hand, making it impossible to close the lid of the fusion splicer's grip. Therefore, a new mechanism was adopted that automatically closes the grip lid to secure Optical Fiber in place, even if both hands are occupied.

|

|

Furthermore, to shorten the time it takes to remove Optical Fiber after fusion splicing, the wind shield and the cover for holding Optical Fiber are linked together to open automatically, and a newly designed high-speed heater has been incorporated to shorten the time it takes to heat and shrink the protection sleeve.

Additionally, this product is packed with features that enhance ease of use, such as an adjustable monitor, a removable battery pack, and a work tray that can be expanded to suit the work environment.

|

|

In addition, the new model continues to feature the popular "ACTIVE FUSION CONTROL TECHNOLOGY" *2 that automatically controls discharge conditions, and "ACTIVE BLADE MANAGEMENT TECHNOLOGY" *3 that wirelessly manages the status of Optcal Fiber cutter blade, reducing the need to rework fusion splices through stable, low-loss connections.

As a result, this product improves work efficiency during fusion splicing and helps to alleviate labor shortages at work sites.

As expectations for the construction of Optcal Fiber networks grow around the world in preparation for the development of an advanced information society, Fujikura will continue to contribute to the development of high-speed information infrastructure.

*1 Approximately 30% reduction in work time compared to Fujikura previous model

These are the results of tests conducted by Fujikura under certain conditions.

*2 "ACTIVE FUSION CONTROL TECHNOLOGY"

A function that analyzes the cut end surface condition before fusion splicing and Optical Fiber thermal emission intensity during discharge, and controls discharge in real time

*3 "ACTIVE BLADE MANAGEMENT TECHNOLOGY"

The fusion splicer monitors the condition of Optical Fiber cleaver blade, and when it detects wear on the blade, it automatically rotates Optical Fiber blade via wireless communication.