Press Releases

Launch of IoT solution for preventing heatstroke - Contributing to the prevention of heatstroke with a proprietary "heat index" monitoring system -

Fujikura Ltd.

June 25, 2020

Fujikura Ltd. (President: Masahiko Ito) has launched a heat stroke prevention IoT solution that measures the heat index (WBGT), which is used to prevent heat stroke, with a completely wiring-free sensor node equipped with a dye-sensitized solar cell developed by Fujikura that requires no power or communication lines, and makes it "visible" and alerts the user.

Background and Issues

In recent years, the increase in the number of people being rushed to hospital with heatstroke has become a major issue related to safety in daily life. Relevant ministries and local governments have also stepped up their efforts to resolve the issue, and various measures, such as measuring and using the heat index, are being considered and implemented. The risk of developing heatstroke is highly dependent on the environment, and even in places that require special caution, such as schools, construction sites, and nursing homes, the environment varies greatly from place to place. Therefore, it is important to understand the heat index through detailed measurements for each individual location in order to prevent heatstroke.

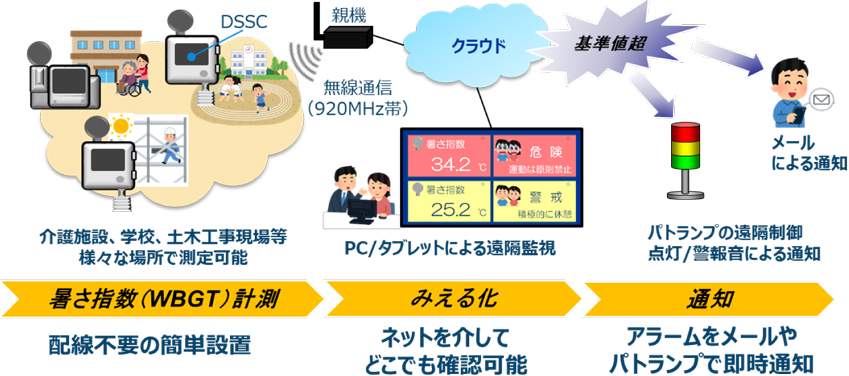

To solve this problem, Fujikura developed a heat index sensor node with a black ball to "visualize" the heat index, monitor it, and develop an IoT solution for preventing heatstroke that sounds an alarm and notifies people when the measured value exceeds a threshold and the risk of developing heatstroke increases.

|

Heatstroke prevention IoT solution system configuration |

Strong Point/Feature

1. Sensor node

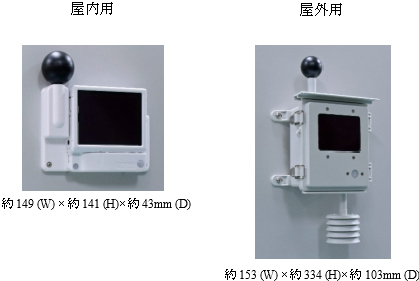

The sensor node we developed is equipped with a dye-sensitized solar cell (DSSC), an energy-harvesting device developed Fujikura, so it can run on its own power source as long as there is a certain amount of illuminance, and data transmission is carried out via wireless communication in the 920 MHz band, so it can be easily installed without the need for power wiring or communication wiring work.This allows for installation in a short construction period, keeping implementation costs low, and also significantly reducing maintenance costs required for battery replacement.

Furthermore, the inclusion of a black globe temperature sensor that measures radiant heat enables accurate WBGT measurement (compliant with JIS B 7922 Class 2). By integrating this black globe temperature sensor with the sensor node, not only has the complexity of installation been reduced, but implementation costs have also been further reduced.

For data transmission, we offer a multi-hop communication model with high obstacle avoidance performance and a LoRaWAN™ communication model that is capable of long-distance communication of several hundred meters to 10 km, allowing you to choose the wireless method that is best suited to your installation environment.

|

|

2. "Visualization" cloud application

At the same time, we have also started offering a cloud application called "Visualization" that can be used effectively to prevent heatstroke. Using this application, you can view current and past heat index data from multiple locations where sensor nodes are installed on the management terminal screen anytime, anywhere via the Internet. In addition, when the heat index exceeds a set threshold, the application has a function that changes the display color on the management terminal screen, sounds an alarm, and sends an alarm by email in a timely manner, making it possible to encourage relevant parties to take prompt action.

As part of its heatstroke prevention IoT solution, Fujitsu will contribute to preventing heatstroke by providing a comprehensive range of solutions, from high-performance device hardware to cloud services that make the most of this hardware.