CO2 Emissions Reduction (Climate change measures)

Policy and Guideline

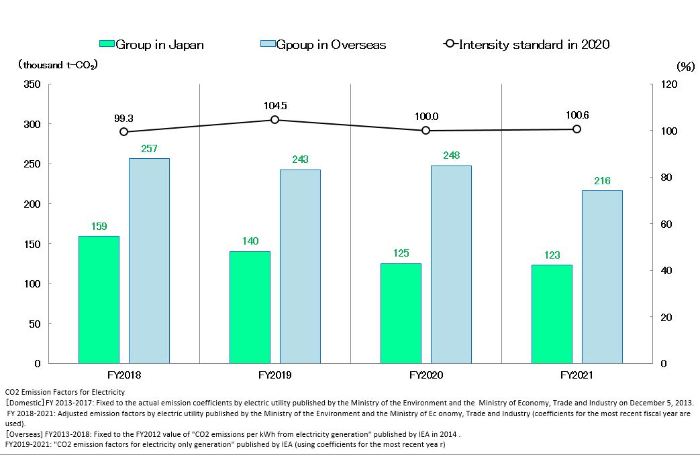

FY2018 was re-established as the base year for calculating reduction in total CO2 emissions, as we set the goal of reducing total CO2 emissions in FY2025 by at least 332,000 tons/year (at least a 20% reduction compared to FY2018).

Concept of the Base Year and Intensity Levels of CO2 Emissions

- Fujikura Group CO2 emissions are calculated by multiplying the energy used in each fiscal year for each type of energy by the CO2 emissions factor for each type of energy.

- Fujikura has complied with the use of market standard emissions factors indicated in the GHG Protocol Scope 2 Guidance.

- Conversion factor

- Electric power in Japan: Adjusted emissions factors for electric power providers in the most recent year, published by the Ministry of the Environment and the Ministry of Economy, Trade and Industry

- Overseas electric power: Emissions factors by country, published by IEA

- Fuel in Japan and overseas: Emissions factors for the most recent fiscal year published by the Ministry of the Environment

Total GHG Emissions and Energy Usage

Total GHG emissions in FY2021 amounted to 339,000 tons, all of which were CO2 emissions. Emissions in Japan totaled 123,000 tons, while overseas emissions totaled 216,000 tons.

Offsetting of CO₂ by non-fossil certificates in Japan and abroad.

・Domestic: 0.15 thousand tons of J-Credits, 0.44 thousand tons of FIT Non-Fossil Certificates

・Overseas (Thailand): 13,000 tons of I-RECs

Electricity accounted for 93% of energy used and fuel for 7%.

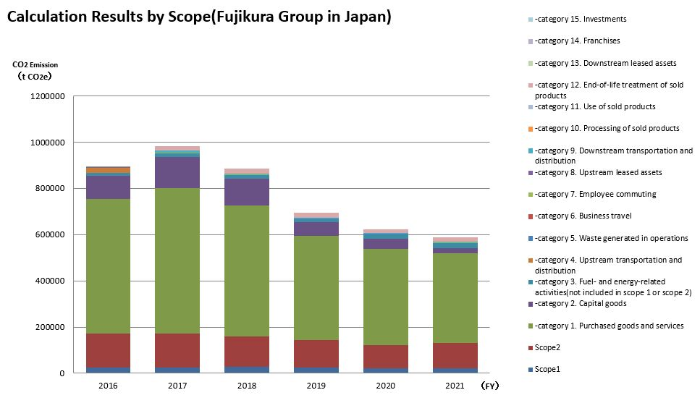

Following the establishment of Scope 3 criteria in 2011, the GHG Protocol* requires companies disclose information on CO2 emissions not only for our own business activities but also for the entire supply chain. Fujikura continued to perform a simple calculation for all Scope 3 categories of the GHG Protocol.

- *The Greenhouse Gas Protocol: A set of calculation standards for greenhouse gases created mainly by the World Business Council for Sustainable Development (WBCSD) and the World Resources Institute (WRI).

|

|

Activity Results for FY 2021

In FY2021, we conducted activities with the goals of "reducing CO2 emissions by 4% or more compared to fiscal 2018" and "improving basic unit of production energy by 2% or more compared to fiscal 2020. CO2 emissions for the entire Fujikura Group, including offsets by non-fossil certificates, were 339,000 tons, a decrease of 18.4% from fiscal 2018. Unit energy consumption for production deteriorated by 0.6% compared to FY2020, falling short of the target. The main reason for the failure to achieve the basic unit target was a significant decrease in production volume due to a decline in orders for FPCs, the main product of our overseas production bases. In addition to the CO2 emissions reduction target, we are also working to promote energy conservation by improving production efficiency. In particular, we are promoting energy conservation activities through planning and periodic progress checks by the "Energy Conservation Promotion Team" in order to achieve the goal set based on the roadmap for the CO2 Emission 2050 Zero Challenge, which is to improve the energy consumption rate per unit of production by 10% or more in FY2025, compared to the FY2020 level.

Specifically, we have promoted activities under the common theme of energy conservation through efficient facility operation, and achieved energy reduction equivalent to about 330 million yen for the entire company in FY2021. In addition to the continuous implementation of the elimination of energy loss through the use of the holiday mode, which minimizes power consumption of air conditioning, compressed air, cooling water, etc., during non-operating hours, mainly at night and on holidays, measures to keep heat dissipating parts warm, and measures to prevent factory air and steam leaks, the entire company worked to minimize power consumption when manufacturing facilities are not in use.

|

|

Activities in Transportation and Logistics

The target for fiscal 2021 was a 1% improvement over the previous year's 41.2KL/kiloton in terms of energy consumption per unit of production for logistics activities. The actual result for FY2021 was 41.7 KL/kiloton. The target was not achieved due to the continued impact of a decline in the loading rate due to a decrease in shipments by major shippers as a result of the Corona vortex.

In addition, we are continuing to promote the efficient use of resources, and are promoting the reuse of packaging materials and wooden drums. Furthermore, we are actively promoting the use of a two-tier stacking jig (official name: electric wire drum pallet) developed to improve the loading rate.

With regard to the improvement of energy consumption rate per unit of production associated with logistics activities, we set a target of 1% improvement in fiscal 2021 compared to fiscal 2020, compared to the previous year's actual energy consumption rate of 41.2 kl/kiloton. The actual result for FY2021 was 41.7 KL/kiloton. The target was not achieved due to the continued impact of a decline in the loading rate due to a decrease in shipments by major shippers as a result of the Corona vortex.

In addition, we are continuing to promote the efficient use of resources, and are promoting the reuse of packaging materials and wooden drums. Furthermore, we are actively promoting the use of a two-tier stacking jig (official name: electric wire drum pallet) that we developed to improve the loading rate.

Reuse of Packaging Material and Wooden Drums

|

Electric Wire Drum Palette |

|

Energy Conservation Initiatives

Promotion of Ministry of the Environment Campaigns

As a group of companies that is mindful of the environment, the Fujikura Group participates in the COOL CHOICE campaign for preventing global warming ahead of 2030 being implemented by Japan’s Ministry of the Environment. We are implementing active initiatives under this campaign. In addition, we also participate in the energy conservation and Cool Biz campaigns in the summer and Warm Biz campaign in the winter.

Eco-tuning

The Real Estate Company is working to reduce wasted electricity use and CO2 emissions through eco-tuning and return the cost savings to tenants and building owners.

The eco-tuning touted by the Ministry of the Environment is a method of detailed analysis and diagnosis of the conditions of use for existing equipment and systems and pursuing energy conservation efficiently without sacrificing comfort and productivity.

In FY2021, we reduced CO2 emissions by 43.8 tons by optimizing cooling water temperature, improving pump transfer efficiency, optimizing ventilation fan operation time, and changing elevator cooling temperature settings for one of the five Fujikura-owned rental office buildings. We will continue to implement eco-tuning for the remaining four buildings.v

Energy Conservation Initiatives at Business Sites

At the Sakura Plant, energy was saved through efficient operation of compressors. At the Suzuka Plant, the plant, which was restarted in response to increased production of optical fibers, optimized the temperature setting of air conditioners to reduce the increase in power consumption.

At the Numazu Plant, a holiday mode was implemented in which boiler facilities were shut down on weekends, resulting in a 27% reduction in city gas consumption.

Energy Conservation Initiatives at Group Companies

At our manufacturing sites in Thailand, energy conservation committees have been established to set targets, manage progress, and share information to promote energy conservation at multiple plants in unison. We have achieved significant energy savings for utility and facility equipment such as air conditioners and compressors, mainly by controlling holiday modes and the number of units in operation. In the future, we will also focus on energy conservation for manufacturing facilities.