Expansion of Environmentally Friendly Products

Environmentally Friendly Products

The Fujikura Group performs environmental assessments of products in the product planning, development, and design stages to evaluate the environmental friendliness of each product throughout its entire lifecycle to improve environmental performance.

Products that meet the standards are certified as "green products" or "green mind products". Our target is to register at least 60 environmentally friendly products every year.

In FY2021, Suzuki Giken Co., Ltd. joined our activities. We will continue to promote joint activities with other group companies to increase the contribution of environmentally friendly products to our group's earnings.

|

|

The Fujikura Group has established a Green Related Product Certification System to promote the development of environmentally friendly products from the perspective of global environmental protection. The Product Environmental Assessment Check Sheet submitted by each business unit is reviewed by the Green Product Management Committee, and products that score above the standard are registered as green products. The Product Environmental Assessment Check Sheet was established in 2011 and is updated regularly. The Green Product Management Committee is chaired by a member of the R&D department and includes members from each business unit. The certification of green products is based on Type II environmental labeling as stipulated in ISO 14021.

In FY2021, 54 green minded products were newly registered for the entire group companies, and approximately 3,000 existing FPC products that are RoHS compliant were additionally registered. As a result, the ratio of green-related products (total of green minded products and green products) to net sales reached 55%.

Environmentally Friendly Products

Spider Web Ribbon® (SWR®) and Optical Cable Using SWR®

Purpose of use: High-density optical cable for FTTx and large-scale data centers

Environmentally Friendly:SWR®, in which single optical fiber strands are intermittently bonded, forms a ribbon-like construction that can easily be reshaped. As a result, the slot protection used when bundling fibers into a cable is no longer needed and we were able to reduce the outer diameter and weight of the cables themselves by up to 60%.

We were also able to include a higher fiber count in cables using SWR® by reducing the diameter of fiber strands from 250μm to 200μm, without increasing the outer diameter of the cable. This also reduced the weight. We also used the same fiber pitch for 250μm and 200μm fibers, which made fusion splicing of both possible. This contributes to improved productivity during installation work.

|

|

Rack-mountable optical connector termination cabinets

Prurpose of use: Optical connector termination cabinets equipped with optical cables for data centers

Environmental Considerations: Fujikura successfully developed an optical termination cabinet that accommodates high density and is easy to maintain. This termination cabinet enables storage of 1.5x the number of optical fiber cords compared to similar products of other companies and contributes to resource conservation. Normally, when a cabinet is simply packed to high density, it makes it harder to insert and remove cables. However, the use of a sliding mechanism for the connector trays has made it possible to easily and safely insert and remove connectors without making maintenance more difficult. The use of SWR®/WTC® has also made it possible to use smaller-sized cables and has increased the number of fibers that can be inserted in racks and pass through ducts.

|

|

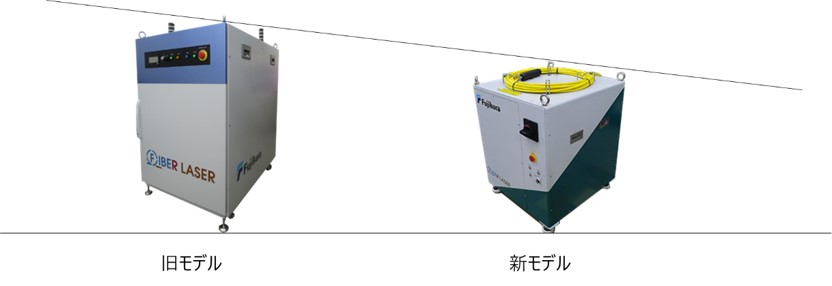

Cabinet-type high-power fiber laser

Purpose of use: Industrial Laser Processing

Environmentally Friendly: By downsizing the fiber laser module, which is the building block of high-power fiber lasers, we have achieved a downsizing of the final product, a cabinet-type high-power fiber laser. By reviewing the layout, design, and components within the fiber laser module, the footprint was reduced by 40% while increasing the laser output power. As a result, the volume and weight of a high-power fiber laser processing machine consisting of multiple units of this module have been reduced by 60% and 40%, respectively, compared to a conventional product of the same output. In addition, by reviewing the components used and optimizing the design, power consumption has been reduced by 20%. Assuming an annual operating time of 2000 hours, the annual power consumption can be reduced by 10,800 kWh per machine, which contributes to an annual reduction of approximately 6 tons of CO2 emissions.

|

|