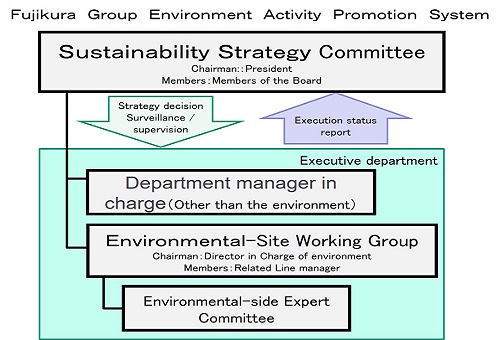

Environmental Management System

Global Environment Activity Promotion System

|

The overall environmental management activities of the Fujikura Group are managed by the Global Environment Committee, which is the environmental site working group of the Sustainability Strategy Committee*. The Global Environment Committee deliberates and makes decisions on environmental management and the officer in charge of the environment (senior managing director) serves as the committee chair. The committee formulates annual and medium-term targets on climate change and other aspects of the environment and monitors progress on activities. Upon approval of the committee chair, the committee reports to the Sustainability Strategy Committee, which is chaired by the president. Specific activities include setting annual and medium-term goals, formulating plans according to these goals and monitoring the progress of plans. For addressing priority themes, special teams which support the planning of measures and ensure implementation of measures across the Group are organized under the committee as necessary. |

|

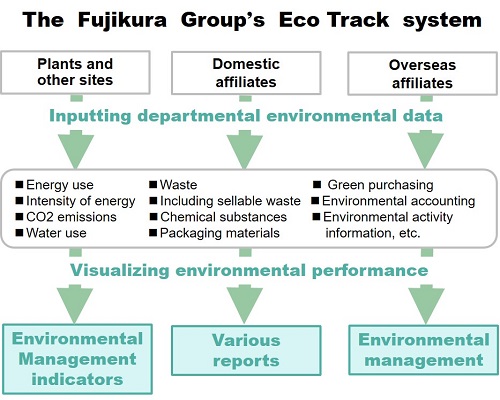

Fujikura Group EcoTrack Environmental Information Collection System

|

The Fujikura Group uses the EcoTrack environmental information collection system to collect environmental data such as the amount of energy, water, and chemical substances used, the amount of waste generated, and the results of environmental activities by 22 consolidated companies in Japan (100%) and 45 overseas consolidated companies (65%, excluding the holding company). The environmental data and environmental results collected are aggregated and analyzed, then used to formulate environmental management indicators. The aggregated, analyzed results are shared within the Group to visualize the status of Fujikura’s environmental impact and the results of activities to mitigate that impact. |

|

Environmental Education

The Fujikura Group involves employees in energy saving and recycling activities, implementing environmental education so that all employees work to protect the Earth's environment during their daily work. The Fujikura Group raises awareness using environmental lectures during new employee training, by regularly holding OJT in the workplace as well as regular specialized training on ISO 14001 education and operations at the site as well as workplace level.

Training Activities at the Head Office and Business Sites

(Head Office) Implementation of Internal environmental auditor training

|

A study session for internal environmental auditors was held at the head office in November. |

*The image is from 2019 |

(Sakura Works) New Employee Training

|

Every year at the Sakura Works, we provided environmental training to new employees with determined job assignments. In FY2020 training was also conducted in April for business site hires and in May for head office hires. |

|

(Sakura Works) Waste Sorting Training

|

A wide variety of waste is generated by the research and development and other divisions. In order to properly consign each waste material, waste sorting training at the waste disposal site is conducted twice a week (about 100 times a year). |

|

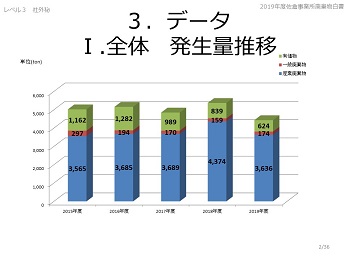

(Sakura Works) Issuance of a white paper on waste

|

The Sakura Works published the 2019 White Paper on Waste. Information such as waste classification is described in addition to the amount of waste and valuable resources generated and the processing amount. It is also effectively used as a departmental education material and as a hint for improvement activities. |

|

(Suzuka Works) General Environmental Education

|

General environmental education is implemented every year for all employees of the Suzuka Works.Training was held for the entire plant up to FY2019. In FY2020, it was held for each work site to prevent the spread of COVID-19 and 388 people received the training. Through the training, we deepened our understanding and cooperation for energy saving and waste reduction, and raised each person's environmental awareness. |

*The image is from 2019

|

(Numazu Works) Plant wastewater security officers trained in wastewater monitoring items

|

Training on wastewater monitoring items was provided for the security officers who monitor the final treatment plant for wastewater from the Numazu Works. The training was conducted to improve their awareness of monitoring operations by educating them on the environmental impact of each item and explaining legal regulations, etc. They will continue to perform monitoring in accordance with the rules and will take swift action when an abnormality occurs. |

|

(Ishioka Works) Monitoring and measurement of wastewater

The Ishioka Works is located in the basin that flows through Kasumigaura, and its drainage standards are considered to be one of the strictest areas in Japan. For this reason, in addition to weekly water quality measurements, the terminal drainage basin constantly monitors pH, oil film, and turbidity with a monitoring device. Furthermore, the pH and oil film are constantly monitored at the drainage monitoring pits of Fujikura Components and Fujikura Hyopt in Factory A. We strive not to drain water that exceeds the drainage standard values of Ibaraki Prefecture and Ishioka City to the outside of the office.

|

|

|

|

Environmental Education Activities at Group Companies

(Yonezawa Electric Wire Co., Ltd.) Regional environmental conservation activities

We hold an annual spring clean-up of the ditches and roads in the northern industrial zone in Koriyama city where Head office and Koriyama plant are located.

|

|

|

(Numazu Copper Refining and Rolling)Environmental emergency response drill conducted

|

Numazu Copper Refining and Rolling Co., Ltd. conducted a drill for all workers in the refinery, based on a scenario in which oil leaks out of the conveyor vehicles in the refinery. Drills on specified emergency conditions are conducted each year so that we can continue our record of zero environmental incidents. |

|

(Fujikura Solutions Ltd.)New Employee Training

|

Fujikura Solutions Ltd. used Microsoft Teams to conduct ISO 14001 Internal Auditor Training in November of this fiscal year due to the COVID-19 pandemic. Registered internal auditors mainly consist of mid-level managers. |

|

(Fujikura Automotive Asia Ltd.) Green activities: Neighborhood trash pick-up near plant

Fujikura Automotive Asia Ltd. picked up trash in the neighborhood near the main plant as one of its environmental activities to contribute to the community. Around 70 people participated and collected 25 kg of trash. Cleaning up the neighborhood near the company somehow lifted our spirits. We will continue this in the future, to the extent possible.

|

|

|

(DDK Ltd.) Switched to LED lighting as an energy-saving initiative

|

We switched 74 lights to LED lights in the Ishibashi head office and warehouse as an energy-saving initiative that can be expected to reduce electricity use. We anticipate a reduction in electricity use of 6.9 kWh/year and a cost savings of 186,000 yen. |

|

(Nishi Nippon Electric Wire & Cable Co., Ltd.) Environmental conservation activities

The Oita plant works to raise environmental awareness by soliciting and posting environmental posters and having representatives from each division perform “3 S” (sort, set in order, and sweep) cleaning activities on the north side (seaside) of the plant as part of Environment Month (June) events. Participants removed unnecessary items, weeded, and performed other maintenance tasks to prevent debris from entering the Seto Inland Sea next to the plant. Actually participating in this activity enhanced awareness of environmental conservation among participants.

|

|

|

Environmental Audits

We carry out regular environmental audits on each of the Group’s domestic manufacturing sites.During an audit, the audit team confirms the status of management of equipment, waste, hazardous goods, and dangerous goods, and other items, and compliance with ordinances and legal regulations. They follow up on corrective measures implemented to address environmental problems, and confirm other environmental impact mitigation activities. When necessary, the audit team provides guidance and support, and works to improve the level of environmental conservation and management at each site.

In FY2020, strong restrictions were imposed on performing in-person audits due to the impact of the COVID-19 pandemic. The only in-person audit was performed at the Fujikura Sakura Works. We will consider audit methods and perform audits as we continue to work under similar conditions in FY2021.

2020 Internal Environmental Audits Site

| Fujikura Ltd. | Sakura Works |

|---|---|

| Group Companies |

Environmental Accounting

The Fujikura Group discloses environmental accounting data in line with the Ministry of the Environment's Environmental Accounting Guidelines 2005. Environmental accounting serves as a tool to evaluate the effects of environmental protection activities in a quantitative manner. By using this tool, we can identify the costs and effects of environmental protection activities, evaluate improvements made through these activities, and make use of evaluation results.

Scope of Data

- Period Covered: April 2020 to March 2021

- Scope: Fujikura and 20 Group Companies

| Fujikura Ltd. | Head Offie, Sakura, Suzuka, Numazu and Ishioka Works |

|---|---|

| Group Companies | Nishi Nippon Electric Wire & Cable Co., Ltd., Yonezawa Electric Wire Co., Ltd., Fujikura Automotive Asia Ltd., DDK Ltd., Tohoku Fujikura Ltd., Fujikura Components Ltd., FUJIKURA HIGH OPT Co., Ltd., Numazu Copper Refining and Rolling Co., Ltd., Aomori Fujikura Kanaya Ltd., Shinshiro Cable, Ltd., Suzuki Giken Co. Ltd., Fujikura Precision Ltd., Fujikura Solutions Ltd., Fujikura Dia Cable Ltd., Fuji Materials Ltd., Fujikura Shoji Co., Ltd., Fujikura Facilities Co, Ltd., Fujikura Engineering Ltd., Fujikura Logistics Co., Ltd., FiberTech Co., Ltd. |

- Costs

(Units: million yen)

| Details | Investment | Costs | |

|---|---|---|---|

| Business area costs (Pollution prevention costs, global environmental protection costs, resource recycling costs) |

Exhaust gas cleaning equipment repairs and maintenance costs, Waste water treatment equipment repairs and maintenance costs, Light Emitting Diode&Dedicated high-frequency lighting tube costs, Freon gas recovery and destruction costs, Improvement of base metal manufacturing capacity, Thermal barrier painting costs, Wooden drum recycling costs, Factory chiller update | 196.1 | 2991.5 |

| Upstream/downstream costs | Material Information outgoing expenses, Removal cables separation costs, etc. | 0.0 | 5.3 |

| Cost of management activities | ISO 14001 management audit costs, Book budget, Exhibition participation fee, Greening costs, Environment measurement item costs, etc. | 11.1 | 379.5 |

| Research and development costs | R&D of environmentally friendly products | 19.0 | 920.3 |

| Social activity costs | "Fujikura-Kiba Millennium Woods" maintenance costs, Around the plant clean-up activities costs, Community organizations support costs | 1.8 | 15.7 |

| Cost of repairing environmental damage | Air pollution levy, Insurance, etc. | 0.0 | 48.8 |

| Total | 227.9 | 4357.2 | |

- Effects (actual effects only, not including estimated effects)

(Units: million yen)

| Effects on pollution prevention and global environmental protection | 2.4 |

| Effects on resource recycling | 187.5 |

| Upstream/downstream effects | 0.0 |

| Effects on management activities | 0.0 |

| Research and development | 41.6 |

| Effects on social activities | 0.0 |

| Total | 231.5 |

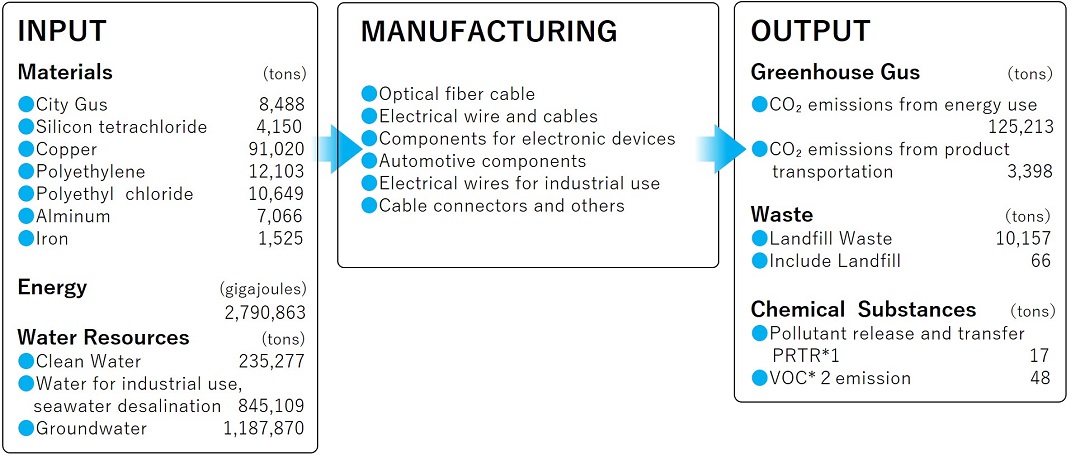

Environmental Impacts from Business Activities

The following shows the major environmental impacts of business activities conducted by Fujikura Ltd. and other Group companies in Japan during fiscal 2020.

|

|

Environmental Compliance

Fujikura sets even higher voluntary standards that exceed laws and regulations. With daily monitoring, regular measurements, and environmental inspections, Fujikura is reducing emissions of chemicals and other substances into the atmosphere and waterways. Also, by strengthening equipment maintenance and implementing equipment measures in advance, we have thorough plans to prevent overages against our standards.

Main Relevant Laws

| Pollution Prevention System Maintenance | Act on Improvement of Pollution Prevention Systems in Specific Factories |

|---|---|

| Land Use | Factory Location Act/City Planning Act |

| Air Pollution | Air Pollution Control Act, Act on the Protection of the Ozone Layer Through the Control of Specified Substances and Other Measures |

| Water Pollution | Water Pollution Prevention Act, Sewerage Act, Private Sewerage System Law |

| Noise/Vibration/Odor | Noise Regulation Act, Vibration Regulation Act, Odor Prevention Act |

| Soil Pollution | Soil Contamination Countermeasures Act |

| Hazardous Materials | Poisonous and Deleterious Substances Control Act, Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof (PRTR law). |

| Employee Safety | Industrial Safety and Health Act (specialization rule, organic rule), Fire Service Act (dangerous substances), High Pressure Gas Safety Act |

| Global Warming Prevention | Act on Promotion of Global Warming Countermeasures, Act on Rationalizing Energy Use, Act on Rational Use and Proper Management of Fluorocarbons |

| Waste Materials | Waste Management and Public Cleansing, Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes |

Environmental Activities and Near-Miss Collection System

Information about environmental troubles regarding Fujikura and its Group companies is quickly consolidated and shared following the Fujikura Group Environmental Trouble Reporting Operations Manual (revised in 2019) to prevent similar troubles from happening again.

Addressing Environmental Complaints

Number of Cases and Countermeasures in FY 2020

In FY 2020, No environmental complaints at Fujikura and group companies.

Violations in FY2020

In FY2020, one case involving violation of environmental limits occurred at Fujikura and Group companies. An incident occurred at the company’s Ishioka plant in which biochemical oxygen demand (BOD) exceeded the permissible limit for Ishioka City. This incident was reported to Ishioka City and we plan to install equipment to remove the substance that caused this. (Installation was completed in September 2021)

Fines and Sanctions

No fines or sanctions have occurred due to violation of environment related laws by any of the business sites or Group companies of the Fujikura Group.