Fujikura's Heat Pipes / Vapor Chambers

Fujikura's Heat Pipes / Vapor Chambers

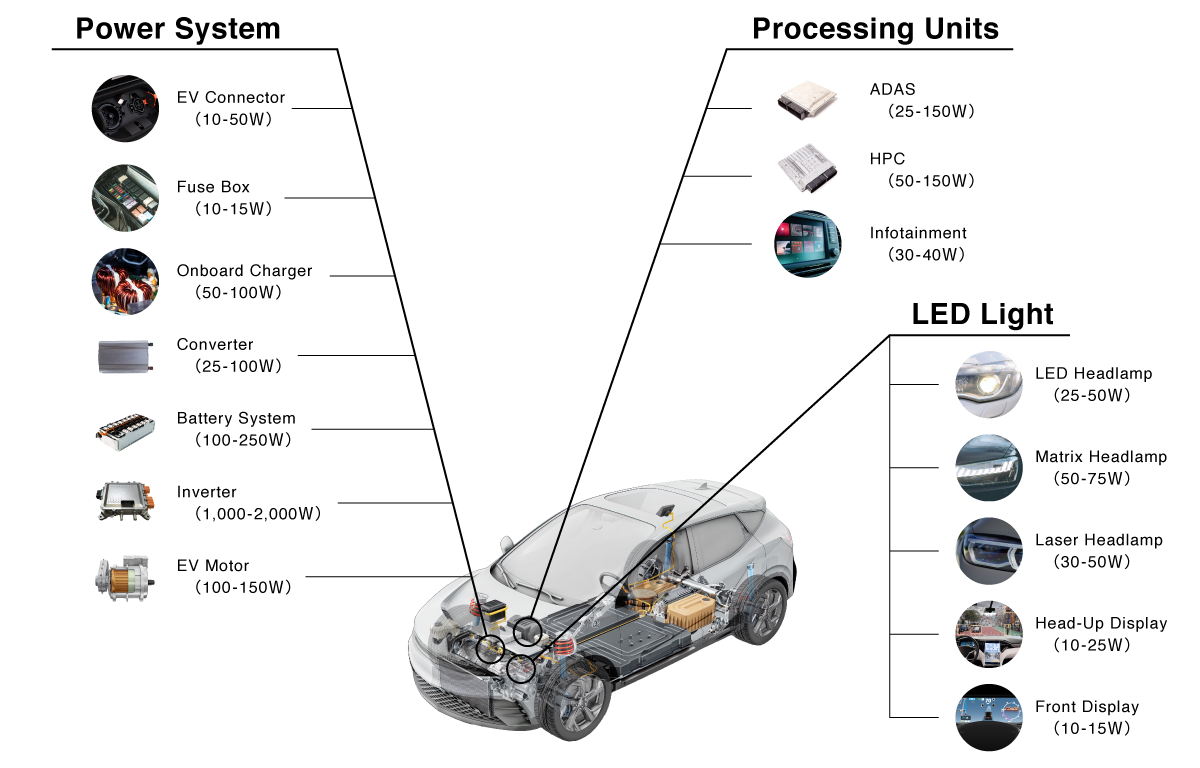

電動化に伴う高出力モーター&バッテリーの搭載

自動運転に伴う高性能プロセッサ搭載数増加

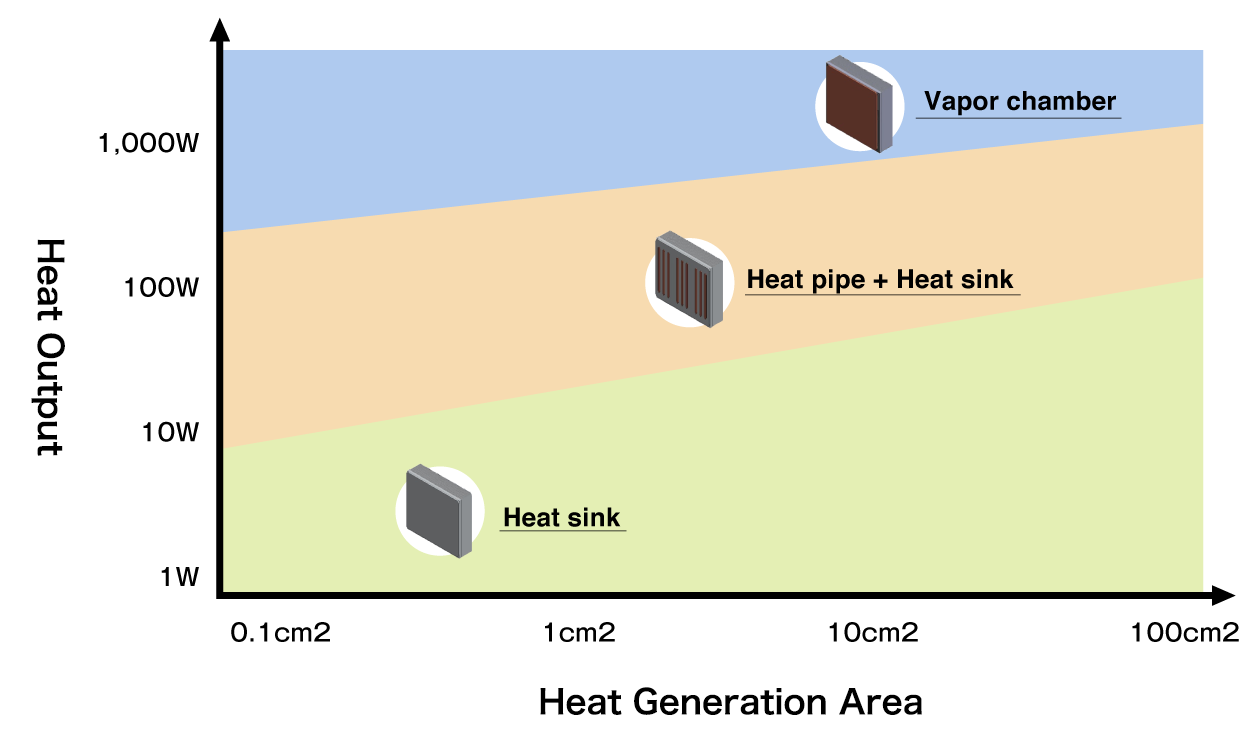

1500Wを超える熱負荷に対しても、高性能を発揮

CPU、GPU、FET等を一つのベーパーチャンバーで冷却可能

VCの実効熱伝導率はグラファイトシートと比較して大幅に高い値が得られています。

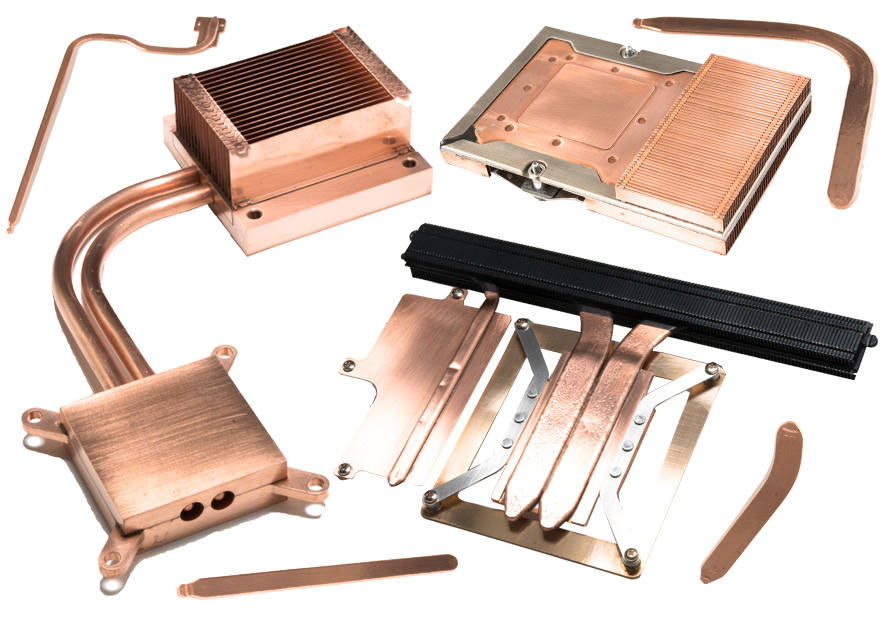

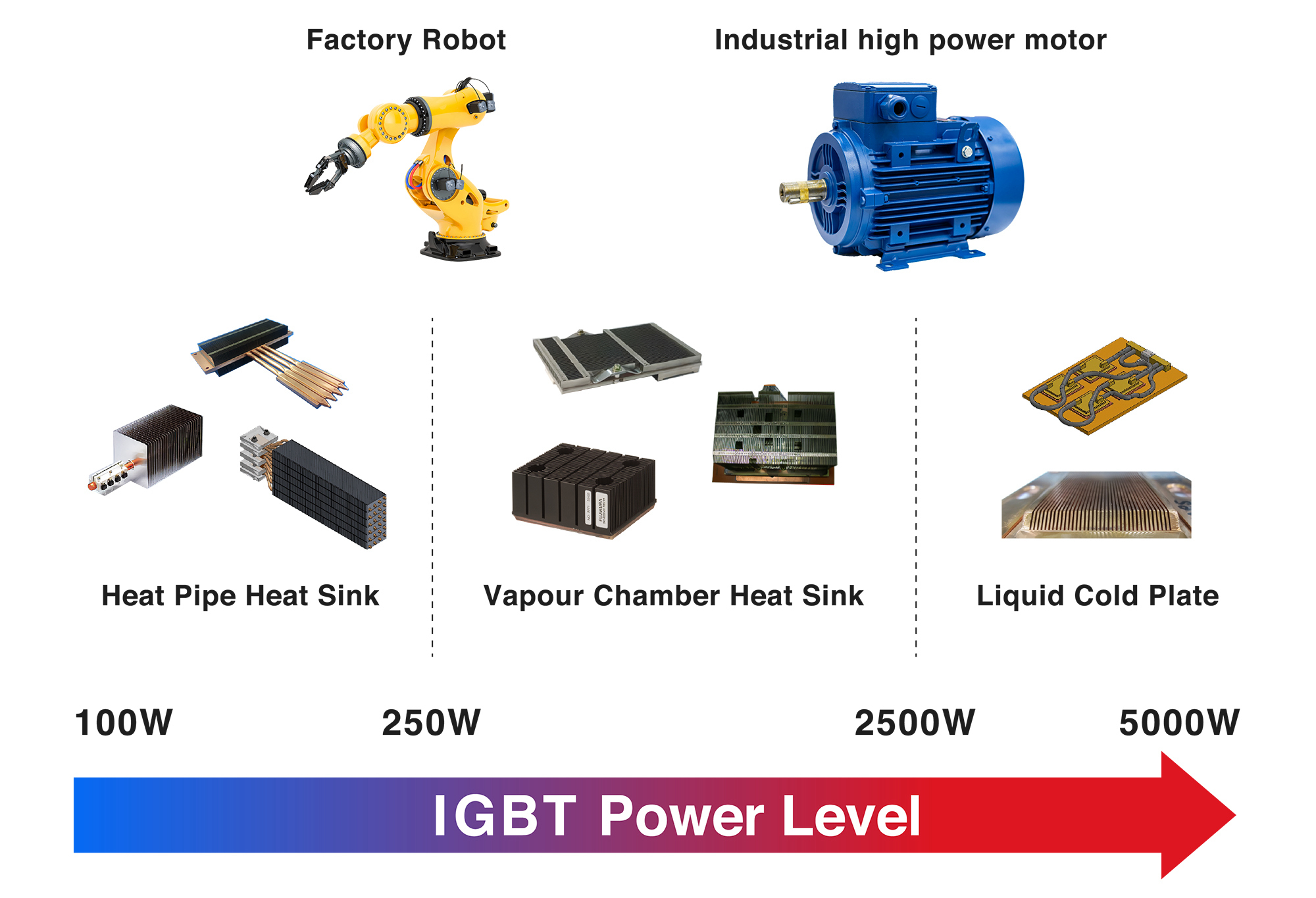

IGBTは、産業機器や電気自動車などの大電力用途で、より高い性能が要求されるため、その数が増加しています。フジクラは、ヒートパイプ付きヒートシンクやベーパーチャンバーなど、様々なIGBTの用途に対応したサーマルソリューションを提供しています。

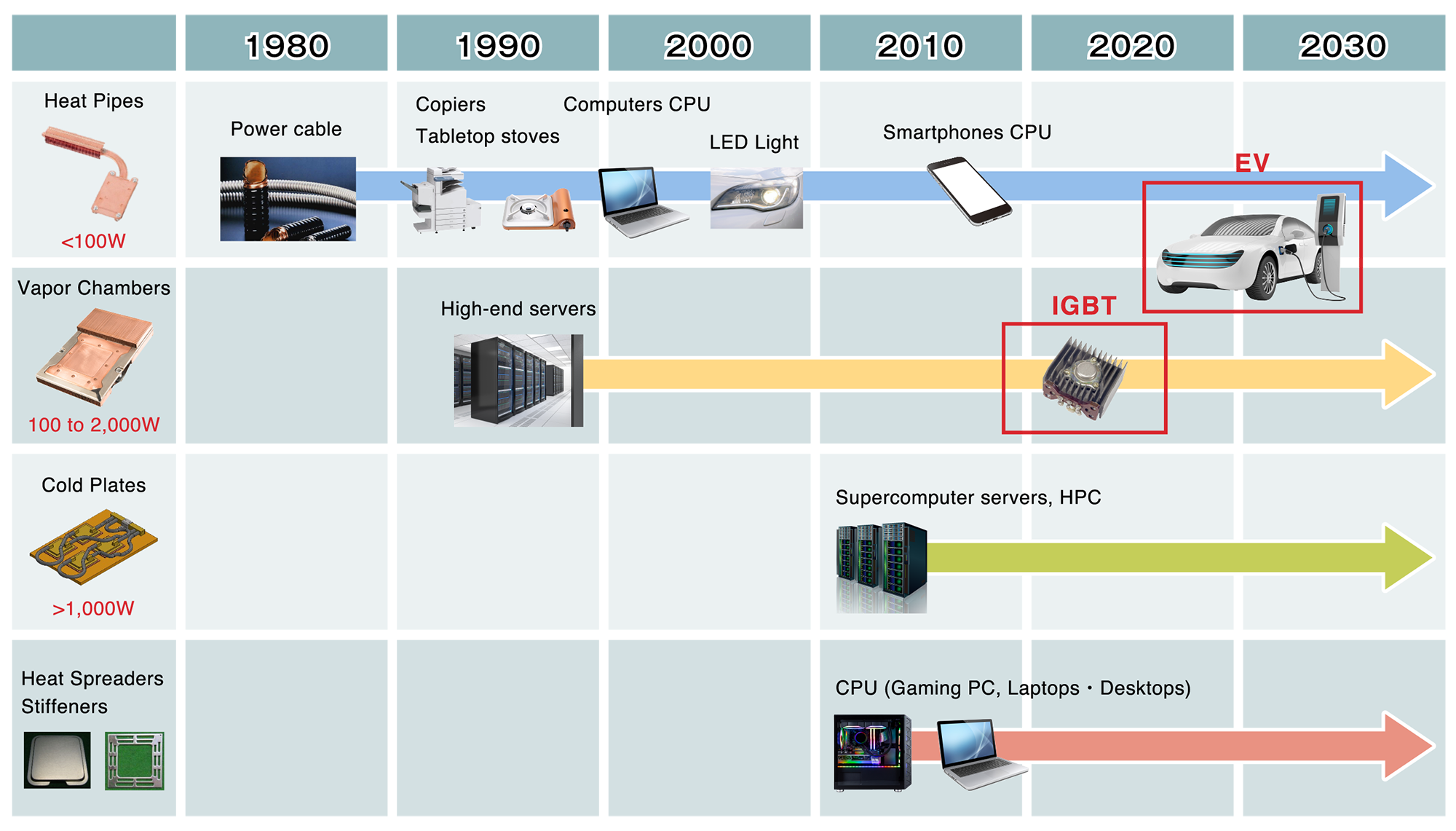

フジクラは、約40年にわたりヒートパイプ・ベーパーチャンバーを供給しております。

今後も、豊富なノウハウ・経験に基づき、電気自動車やパワー半導体など、

新たな領域のお客さまに最適なサーマルソリューションを提案していきます。

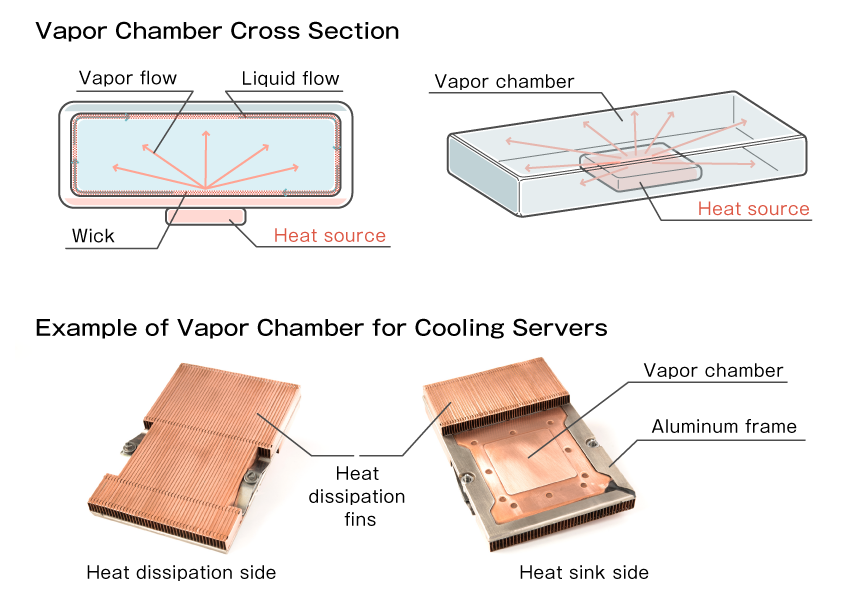

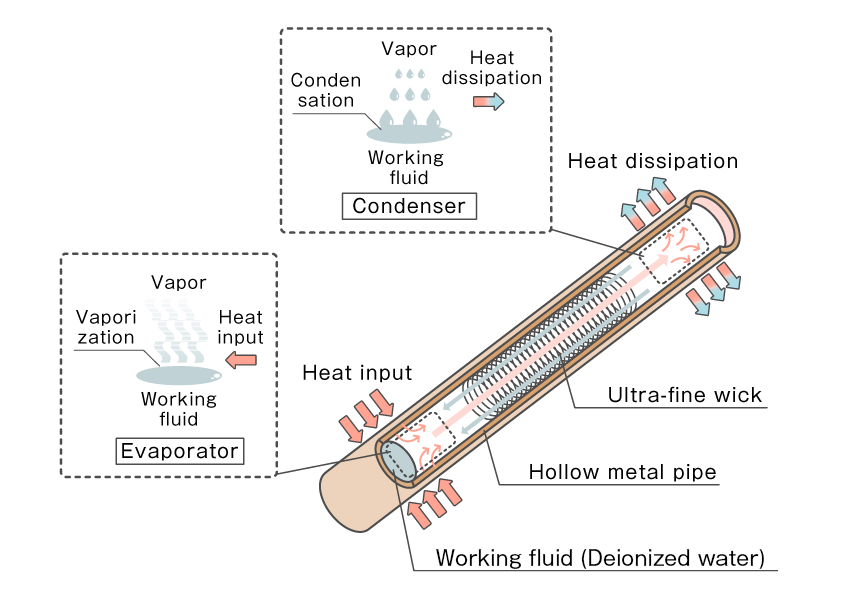

作動原理