Company Profile

Company Profile

| Company name | Fujikura Ltd. |

| Established | 1885 |

| Incorporation | 1910 |

| Paid in Capital | 53.0 billion (as of March 31, 2013) |

| Net Sales | 491.1 billion (FY2012, Consolidated) |

| President & CEO | Youichi Nagahama |

| Head Office | 1-5-1, kiba, koto-ku,Tokyo 135-8512 Japan |

| Plants | Sakura,Suzuka, Numazu, Ishioka |

| R&D | Tokyo, Sakura, Suzuka |

| Branch/Business office | Osaka, Nagoya, Fukuoka, Hiroshima, Sendai, Numazu |

| Overseas | U.S.A, U.K, Singapore, Malaysia, Thailand, China, Vietnam, India, Russia, etc. |

| Number of Employees | 52,409 (Consolidated, as of March 31, 2013) |

| Main Business | Optical Fiber Cable, Optical Tele System, Tele System, Electronics & Auto, Automotive Components, Metal Cable & System, Magnet Wires, Metal Wires, Real Estate Business,etc. |

Global Fujikura Group

|

|

[Number of employees by business segment]

[Unit: 1,000 people]

| Telecommunications | 8 |

|---|---|

| Metal Cable & Systems | 3 |

| Electronics & Auto | 40 |

| Coils and others | 2 |

| Total | 52 |

[Number of employees by region]

[Unit: 1,000 people]

| Japan | 6 |

|---|---|

| Asia (excluding Japan) | 32 |

| Americas | 11 |

| Europe | 3 |

| Total | 52 |

Overseas sales ratio and breakdown of employees

| Fiscal year | 2010 | 2011 | 2012 | |

|---|---|---|---|---|

| Overseas sales ratio | 41% | 44% | 46% | |

|

Breakdown of employees Unit: people |

Japan | 2,575 | 2,607 | 2,585 |

|

Overseas (Ratio) |

50,714 (95%) |

42,246 (94%) |

49,824 (95%) |

|

| Total | 53,289 | 44,853 | 52,409 | |

Introduction of our businesses

Society, industry and our Group

|

|

Business Performance in Fiscal 2012

Posting a decrease in operating income, badly affected by the flooding in Thailand

In fiscal 2012, Japan’s economy showed signs of improvement due to an increase in demand driven by the process of recovery from the Great East Japan Earthquake and also to the weaker yen caused by expectations for the economic recovery measures to be taken by the new administration launched in December 2012. The economy, however, generally remained unstable throughout the year due to the ongoing debt crisis in Europe and a decrease in demand from China.

In fiscal 2012, under these circumstances, the Fujikura Group posted favorable business results in the automotive components business, but the Group’s profitability was badly affected by the intensification of price competition in the matured telecommunication infrastructure market in Japan and the dramatically higher yen. In the electronics business, the damage caused by the flooding in Thailand of October 2011 had a serious impact on the flexible printed circuit (FPC) board business and other businesses, placing the Group in a very difficult situation.

As a result, the Group’s sales amounted to 491.1 billion yen, down 3.5% year on year. Operating income and ordinary income also decreased by 51.4% to 6.4 billion yen and by 86.0% to 1.2 billion yen, respectively. We posted an extraordinary loss of 16.5 billion yen in total, including 9.3 billion yen for the damage caused by the flooding in Thailand and 2.8 billion yen for the cost of implementing the early retirement program as part of structural reform, while posting an extraordinary profit of 21.1 billion yen, including the receipt of insurance money. As a result, we posted net income of 3 billion yen in fiscal 2012, an increase of 9.2 billion yen over the previous fiscal year level.

|

|

|

|

|

|

|

|

Capital Investment

In fiscal 2012, the Fujikura Group (Fujikura Ltd. and its consolidated subsidiaries) made a capital investment of 54.5 billion yen (on a basis of tangible and intangible assets received) under its basic strategies of “concentrating managerial resources in growth fields” and “enhancing craftsmanship in monozukuri (manufacturing).”

| Energy & Telecommunication Systems Company | 12 billion yen | Invested to enhance optical fiber manufacturing facilities in China to increase production |

| Electronics Business Company | 28.7 billion yen | Invested to foster recovery from damage caused by the flooding in Thailand |

| Automotive Products Company | 5.8 billion yen | Invested to improve the metal cable-related manufacturing facilities |

| Other | 8.0 billion yen | Invested in relation to the Fukagawa district redevelopment project |

| Total | 54.5 billion yen | |

Research and Development

Research and Development

Eco-friendly society created by the use of cloud communication technology

|

|

Hiroya Onishi, Manager of the Cloud Communications Business Development Division |

Cloud computing and optical transmission of data

Cloud computing technology has made it possible to transmit all kinds of data between data users and data centers and have the data processed by the servers installed at the centers, thereby increasing convenience for users while also fostering the effective use of resources.

The amount of information exchanged through cloud communication has been dramatically increasing. Specifically, the volume of data transmitted between data users and data centers reaches several hundred gigabits per second per one physical circuit. Even for data transmission within a data center, transmission capacity of several ten gigabits per second is said to be necessary per circuit. Optical cables can transmit high-volume data with high energy efficiency. The cloud communication products of Fujikura represent its “Tsunagu” technology, which help transmit high-volume data with smart wiring and with less power consumption.

|

|

56Gb/s QSFP AOC |

|

|

100 Gbit/s transponder |

New Products and Technologies

■Cooling Technology Supporting Super Computer Cooling Unit

Fujikura has developed a cold-plate type cooling unit as a cooling equipment of super computers for cloud computing. This product is a cooling unit featuring a micro-channel heat-transfer surface and realizes a cooling performance approximately three times that of ordinary air-cooled heat sinks at only one-fifth the capacity. A total of 25,920 of these units are used in the large-scale K super computer to realize cooling of 10 megawatts or more of generated heat. By expanding application of the technologies it has been established during the development and mass-production of cooling units for the K super computer to the cooling of devices such as mainframe super computers , high-end servers, IGBT (Insulated Gate Bipolar Transistor) mounted in power transformers and medical devices, and fiber laser welding devices, Fujikura will contribute both to the solution of cooling problems in electronic devices and the reduction of environmental impact.

|

Cooling unit |

K super computer rack |

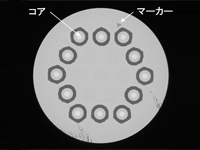

■Achievement of World Record Transmission Capacity using Multi-core Fiber

|

|---|

| Annular Arrangement of Multi-core Fiber used in the Experiment |

*1. Post-deadline paper : A paper that is accepted immediately before a conference to enable competition between the latest achievements just prior to the conference. The ratio of adoption of post-deadline papers is extremely low with only those winning the highest level of acclaim selected.

*2. ECOC : European Conference and Exhibition on Optical Communication One of the most authoritative academic conferences on optical communications held in Europe in September every year.

■Commencement of deliveries of radiation resistant optical fibers to the European Organization for Nuclear Research (CERN)

Fujikura has received orders for radiation resistant optical fibers from the European Organization for Nuclear Research (CERN) and has begun deliveries. On July 4, 2012, CERN announced that "It had measured a particle consistent with the long-sought Higgs boson," and this news was covered in newspapers and on television worldwide. The transmission of data in an environment featuring such high levels of radiation as that of CERN's Large Hadron Collider (LHC) requires a communication network that is resistant to degradation caused by radiation. In 2006, Fujikura's radiation resistant optical fiber was evaluated to be superior to other several companies' products in radiation resistant characteristics at performance tests conducted by CERN, which enabled Fujikura to deliver 2500 km of radiation resistant optical fiber to CERN. Compared to conventional radiation resistant optical fiber, this radiation resistant optical fiber that features improved characteristics is capable of suppressing to a low level the induced attenuation by exposure to radiation in high-dose environments.As a result of re-evaluation for the purpose of maintenance of equipment at CERN of optical fibers supplied by each company, Fujikura was again selected as the future supplier of radiation resistant optical fiber. This radiation resistant optical fiber is capable of meeting severe performance requirements of less than 7 dB/km operating wavelengths of 1310 nm and 1550 nm in a high radiation environment of 100 kGy (Dose rate: 2.6 Gy/s) and is based on international standard of single mode optical fiber. Fujikura will continue to contribute to wide-ranging search by developing special fibers such as radiation resistant optical fiber capable of withstanding severe usage environments.

|

Radiation Resistant Optical Fiber |

The world's highest energy proton-proton collider LHC,located at CERN |

■Development of the World's Largest Yttrium-based 5T High-Temperature Superconducting Magnet

|

|---|

| Developed Yttrium-based High-temperature Superconducting Magnet |

■Dye-sensitized Solar Cells for Energy Harvesting

Recent years have seen the advent of the use of energy in the environment around us as electrical energy and this has resulted in focus on energy-harvesting (environmental power generation) devices that operate without wiring or battery replacement. Fujikura has developed a highly-efficient dye-sensitized solar cell module for energy-harvesting, usage of which is envisaged for indoor fluorescent and LED lighting and a wireless sensor node as an application of this solar cell.Because it incorporates no harmful materials, the dye-sensitized solar cell module is expected to serve as a next-generation environmentally-friendly solar cell. Fujikura’s unique material technology enables the realization of a substantial conversion efficiency of over 20% in a 1000-lux indoor environment with fluorescent or other indoor lightings. Because it is capable not only of high output in ordinary indoor environments, but also of highly-efficient power generation in extremely dark lighting environments in warehouses, for example, it is anticipated that the dye-sensitized solar cell module developed by Fujikura will be capable of usage in an even wider range of scenarios in the future.Moreover, the wireless sensor node developed as an application is a wireless device that requires no battery replacement, making it suitable for use in a wide diversity of fields such as smart houses and plant factories.

|

Dye-sensitized Solar Cells for Energy Harvesting |

|

R&D Laboratories

|

Optics and Electronics Laboratory |

Environment and Energy Laboratory |

Optical Cable System R&D Center |

|

Electronics Components & Auto Center |

Power & Telecommunication Cable System R&D Center |